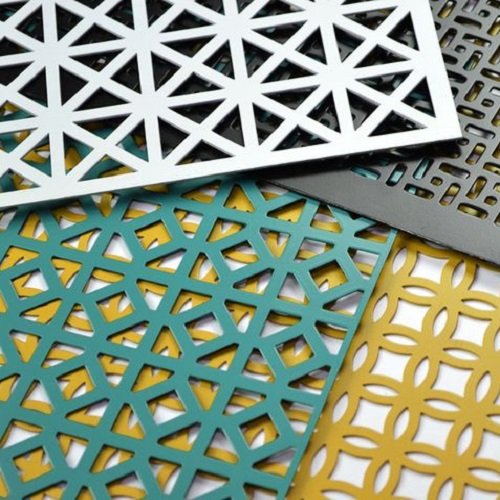

Various Perforation Patterns for Your Projects

Xiongqian provides a variety of perforation holes to meet any decorative requirement. A variety of perforation patterns is available from simple to complicated perforations. Our patterns are available in:

- Square

- Round (staggered and straight)

- Decorative

- Slotted, etc.

Contact us now and we will discuss with you to develop custom patterns.

Advantage of Perforation Pattern for Metal Sheet

A perforated metal sheet comes with different shape patterns. It provides a lot of benefits than a regular sheet. The role of the perforation pattern is to give lighter characteristics to a sheet and allow liquids to pass through.

The perforated sheet is mostly used for filtration. So, you need to consider its perforation pattern, material type, and thicknesses. At Xiongqian, we provide perforated metal sheets with various hole patterns to suit your given application.

- Gallery

Choosing Perforated Sheet Patterns

When choosing which patterns suit your application, you need to consider the following:

- Open Area

- Hole Size

- Hole Geometry

Open Area

- The total measure of metal being removed prior to perforation.

- The open area is the main factor when choosing a perforation pattern as it possessed a direct impact on the sheet’s weight.

- It affects the material’s velocity and amounts such as air or liquid.

Hole Size

- It determines the solid particle sizes that enter into perforated sheets.

- It affects the visibility of the sheet.

- Our circle and square perforation are available in ½” and ⅛” for applications where the smaller hole is required.

Hole Geometry

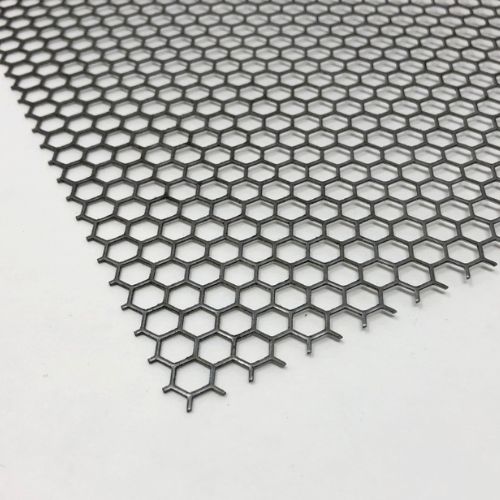

Round

The most used pattern for perforated metal sheets. It is the easiest pattern to perforate and provides a beautifully pleasing pattern. Compared to other patterns, the round hole pattern presents low geometric stress.

The perforated sheet in the round pattern can be straight or staggered. Staggered alignment provides a high number of open areas in each straight-aligned hole. While the straight-hole alignment does not provide a high number of open areas.

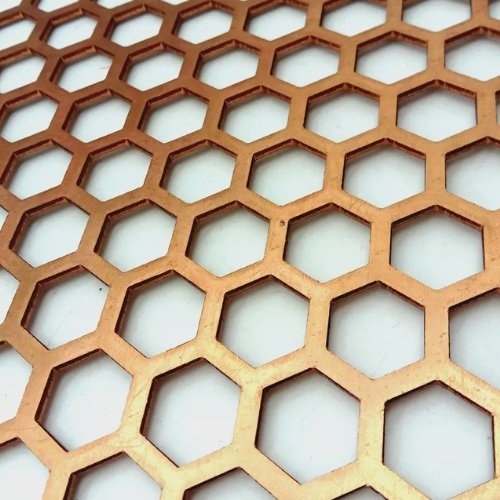

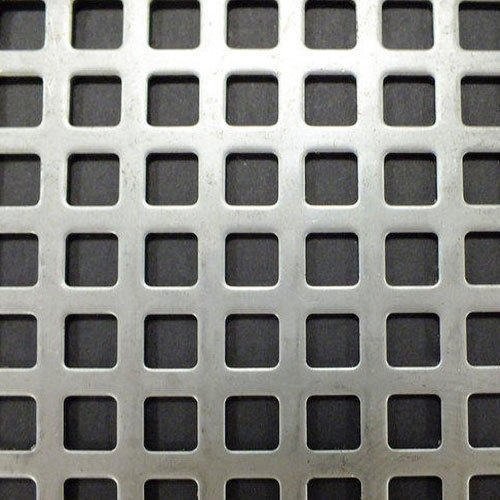

Square

Square hole patterns can be nested. So, it allows a high number of open areas compared to round perforation. A square perforation sheet is widely used in applications that require great airflow.

Square perforation is not easy to form due to its sharp edges, resulting in expensive production. These sharp edges serve as a stress concentrator for the sheet. The square holes are accessible in 0.500” and 0.020” with various spacing amounts.

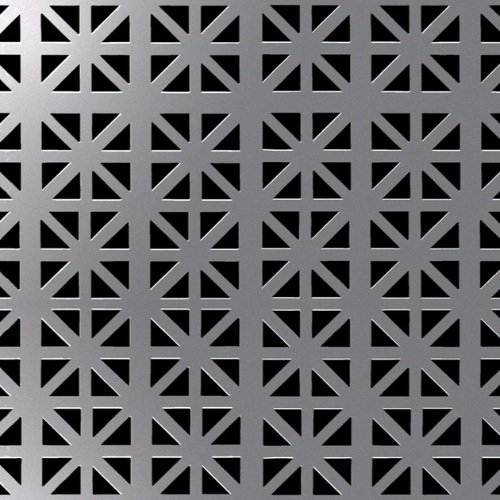

Designer Pattern

The designer pattern is used for an application that needs unique appeal. This pattern includes Grecian, Lincane, and full clover.