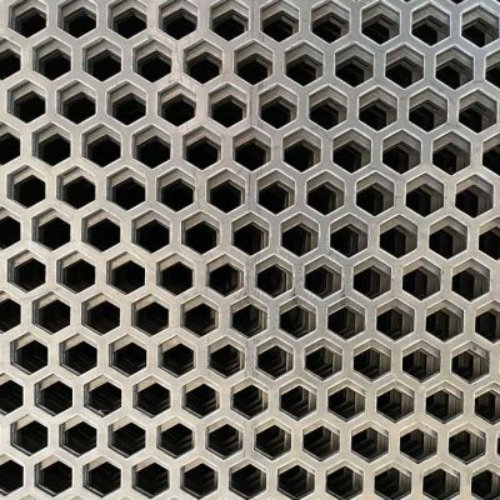

XIONGQIAN Hexagonal Perforated Metal

The perforated metals with hexagonal or honeycomb holes are composed of hexagon-die-punched result holes. They offer more than 80% of open spaces. These unique metal designs provide an attractive appearance and also maximize area security. Moreover, using these perforated metals give minimally compact air and light to the area.

XIONGQIAN professionally manufactures honeycomb perforated metal sheets in different variations. We made them according to your project requirements or business supplies. Our company owns state-of-the-art punching machines, providing your desired hexagonal hole dimensions. Cut-to-size options and shapes are also offered using our advanced facility equipment.

We are able to process high quality hexagonal perforated metal and custom perforated sheet. Contact us now for latest hexagonal perforated metal sheet price!

Metal Material Option for Hexagonal Perforated Metal

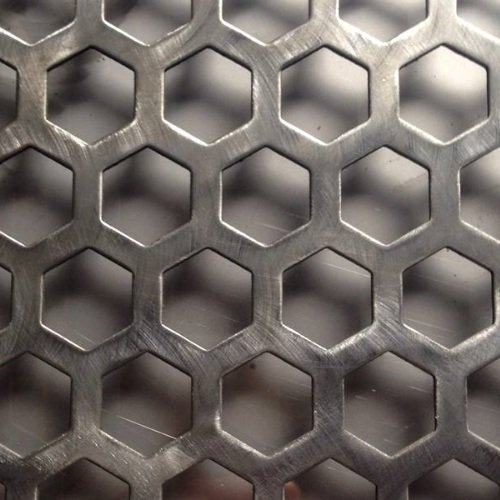

The stainless steel metals with hexagonal holes come with various qualities, including strength and an attractive look. They have chromium content that makes them resist rust.

The aluminum-made honeycomb perforated sheets have lightweight, robust, and adaptable properties. These sheets are ideal for usages that need sound and light diffusion.

Nickel hexagonal perforated sheets have excellent strength. They are the preferred materials used for outdoor construction projects. These sheets can endure extreme temperatures.

Copper-made hexagonal perforated sheets provide great corrosion resistance. They are commonly used for indoor and outdoor projects, providing unique looks according to desires.

The mild steel ones are durable. They are perfect for industrial and commercial utilization that doesn’t need a creative appearance. These sheets are economical with various advantages.

The brass material used to manufacture honeycomb perforated sheets consists of copper and zinc. That makes them possess maximized strength, anti-rust, and hardness.

Why Choose Our Services

XIONGQIAN has unparalleled services offered to customers worldwide. Choosing us as your business or project partner will indeed help boost your sales and productivity.

Consider our following advantageous services:

- Professional staff with deep know-how about metals

- Provides high-quality perforated sheets at a low cost

- Rigorous quality inspection during manufacturing processes and prior to delivery

- Consultation support for free

- Fast delivery

- Significant after-sale service

Related Products

Hexagonal Perforated Metal Advantages

Aside from great corrosion resistance and simple fabrication features, the hexagonal type of perforated metal has the following advantages.

Filters Sound

Installing suitable hexagonal perforated sheets to areas will minimize unnecessary noise through dispersing. They filter out uncomfortable and annoying sounds in working spaces.

Lasting Look

Various metal alloys are used to form hexagonal perforated sheets. That makes them adaptable to process and design with lasting appearance or impression. Since they are metal-made, the unique sheets have high impact resistance and last for a long period.

Privacy

Utilizing hexagonal perforated sheets in workplaces provides an attractive impression as well as privacy. The typical noises are absorbed, forming a calm and pleasant environment.

Ventilation

Industrial buildings use various perforated metals to maximize shades and airflows. This security technique saves about 30% to 50% on heating energy expenses and ventilation.

Environment Friendly

The metal materials used to form honeycomb-perforated metals are recyclable, minimizing new metal needs for production.

Featured Applications for Hexagonal Perforated Metal

The hexagonal perforated metal is a versatile material utilized by numerous industries for applications such as

- In-fill panels

- Trash receptacles

- Ventilators grid

- Drain covers

- Glass reinforcement

- Filters

- Sun protector slats

- Site amenities

- Grain dryers

- Gas purifier

- Stair treads

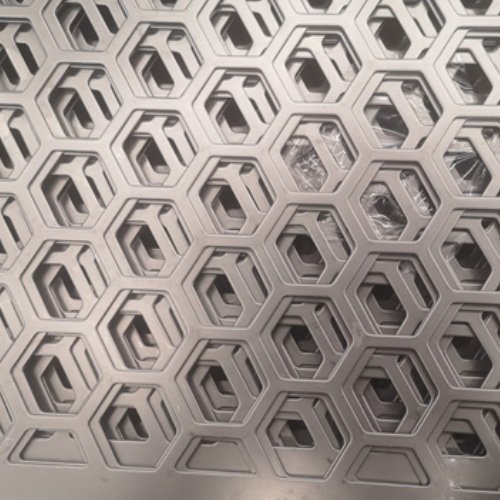

Available Surface Finishes Options for Hexagonal Perforated Metal

- Powder coating

- Oxidation treatment

- Galvanized

- 2B

- Bright annealed

- More

Conducted QC Inspection for Hexagonal Perforated Metal

The perforated metal with hexagonal-shaped holes undergoes several inspections to check its quality.

Consider the following operation.

- Raw material inspection

- Perforated quality check

- Aperture inspection

- Thickness assessment

- Width review

- Length review

Hexagonal Perforated Metal FAQ

What are the Available Hexagonal Hole Sizes for Perforated Metal?

Here are the three sizes categories of hexagonal-type perforated metal sheets, available for customization.

| Dimension | Pitch | Open Area |

| 10mm | 12.5mm | 64% |

| 10mm | 25mm | 32% |

| 14mm | 18mm | 60% |

| 20mm | 25mm | 64% |

| 20mm | 32mm | 39% |

| 22mm | 28mm | 51% |

| 28mm | 33mm | 72% |

| 28mm | 38mm | 54% |

Selecting the Right Hexagonal Perforated Sheets: What are the Factors to Consider?

To find the most suitable hexagonal-type perforated metal sheets, you’ll need to consider the following factors.

- Metal Thickness

- Hexagonal Hole Spaces

- Margins

- Flatness

- Sheet Sizes

What Process Involves Forming Holes in Perforated Metal?

The forming procedures for perforated metal use conventional methods. In most cases, the process now utilizes modern machinery. But, even with a programmed systematic technology, the process remains unchanged.

And the said process includes

- Die and punch

- Plasma

- Rotary pinned

- Laser

- Water jet

- Nibbling

How Long could a Perforated Metal Last?

They are said to last for 50 years with almost no maintenance required. Understandably enough, as perforated metal is composed of numerous materials, it guarantees long-term use.

And also, they are sufficiently durable to withstand damage inflicted by contact pressure. It indicates that perforated metals are long-lasting.