Your Reliable Sheet Metal Fabrication Expert!

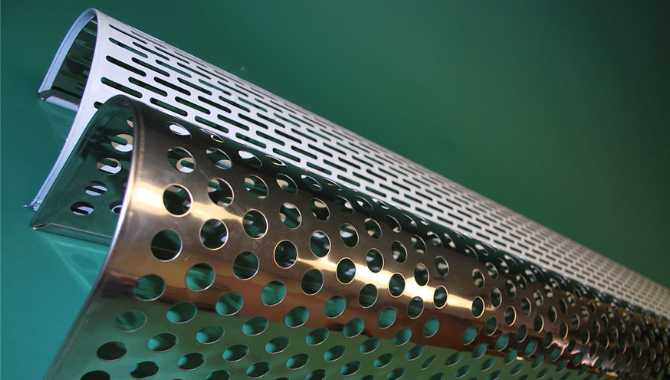

XIONGQIAN has a team of experienced technicians producing quality perforated materials for years. We have the tools and know-how to create the perfect perforated metals for your needs.

We use advanced techniques and state-of-the-art equipment to produce the highest quality sheet metal. Also, we specialize in creating custom perforated materials for different industries –automotive, aerospace, and industrial.

At XIONGQIAN, we understand that trust is essential in terms of sheet metal fabrication projects. That’s why we always strive to provide our clients with the highest service levels and quality.

Our team of certified professionals are experts in all aspects of sheet metal fabrication.

From laser cutting, CNC punching, bending, to welding, and forming.

Laser Cut Process

It uses laser beams to cut precise shapes. This form of sheet metal fabrication uses a non-contact process. This means it does not require the use of cutting tools. Therefore makes it the most efficient method of cutting perforated metal.

The process begins with a CAD drawing which is used to create a vector file. Then the vector file will control the laser beam during the cutting process. The laser beam is focused on metal. Then vaporized and cut into the desired shape.

Laser cutting produces clean, consistent cuts with minimal material waste. Process materials at faster speeds than traditional methods. It also enables intricate designs with high accuracy degree.

CNC Metal Punching

This sheet metal fabrication process uses a computer-controlled machine. The machine will then punch holes into a metal sheet to form desired patterns.

The CNC punching process starts with a pre-programmed pattern or shape being created in CAD (Computer Aided Design) software. This design is then transferred to the CNC punching machine, which uses a series of hydraulic presses and punches to create the desired shape. The press is used to form the metal sheet into the desired shape, while the punches are used to create the holes.

Bending

Bending sheet metal has many advantages, including:

- Ability to create complex shapes

- Ability to create perforated materials quickly and efficiently.

- Allows for the use of thinner material while maintaining desired strength.

When bending sheet metal, there are several factors we consider. These include the type of material being used, the thickness of the material, and the size of the holes. Most importantly, we consider the type of bending machine being used. For best results, we ensure that the material and the bending machine are compatible with one another.

Welding Process

The process of welding involves the use of heat, pressure, and filler material. This creates a strong bond between two pieces of sheet metal.

The two pieces of sheet metal are first cut to the desired shape. Then the edges are cleaned and prepared for welding. Next, the two pieces of sheet metal are placed together. A welding torch is used to heat the pieces until the required temperature is reached. Once the desired temperature has been reached, the filler material is applied to fix the two pieces together.

Forming Process

Forming process forms metal by bending, stretching, or compressing it.

This is done using different forming methods like roll forming, press forming, and die forming. It is also used to create complex shapes and strengthens the metal.

What Makes XIONGQIAN Stands Out

At XIONGQIAN, we pride ourselves on our engineering expertise and our commitment to driving the metal fabrication field forward.

Our dedication to customer satisfaction is unparalleled. And we only provide only the highest-quality perforated materials and services.

We always strive to make our process as streamlined as possible. Integrating seamlessly with yours to ensure you never miss a beat.

Discover the many benefits of our sheet metal fabrication services. Contact us today!