Xiongqian Perforated Titanium Sheet

The perforated sheet made of titanium is heavier than aluminum materials and lighter than steel materials. Titanium has the ability to establish a durable oxide protective layer. These characteristics make the sheets ideal for structural uses.

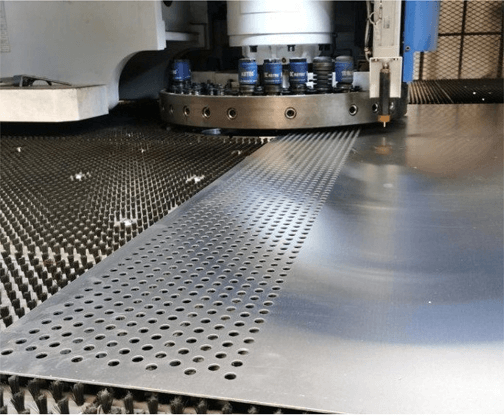

Xiongqian is a leading perforated titanium sheet supplier in China. We supply it in a variety of hole shapes and thicknesses based on different project requirements. With our state-of-the-art machinery, Xiongqian can guarantee to meet your specifications. Our team can also develop the punch design tooling ideal for decorative and architectural metal purposes.

You will get full support from titanium perforated sheet size to mesh holes from us. We can produce special style for your required ex-perforated titanium sheet. No matter you are the end user or distributor, Xiongqian will help you save cost to buy and import perforated titanium from China.

Message us now!

Various Perforated Titanium Sheet For Your Business

You will improve your construction work quality with our Perforated Titanium Sheets. We fabricate ex-perforated titanium panel with latest technique to ensure the perfect performance for your application. As reliable Perforated Sheet Manufacturer, we have got CE, ISO certification on different types of Perforated Sheet.

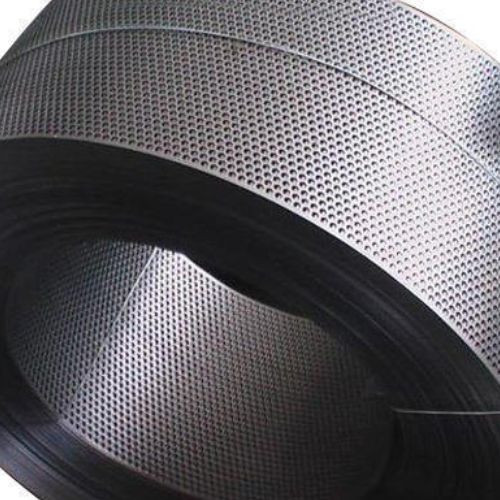

You can buy customized Round Hole Perforated Titanium Sheet from us.

Main Data:

- Thickness: 0.2-20mm

- Hole Arrangement: 90°, 45°, 60° staggered

- Size (mm): 1200×2400, 1000×2000, cut to size

We are able to produce Square Hole Perforated Titanium Sheet in different style.

Main Data:

- Hole: 1/8 to 3/8 inches Dia.

- Size: Customized

- Features: durable, long lifespan, solid structure, corrosion-resistant, low maintenance

Our Slotted Perforated Titanium Sheet is more durable than other supplier, we support free sample for quality check.

Main Data:

- Thickness: 20mm maximum

- Hole Pattern: APLL, APLC, PPLL, PPLC

- Sizes: 1000mm*2000mm, 1500mm*3000mm, customize

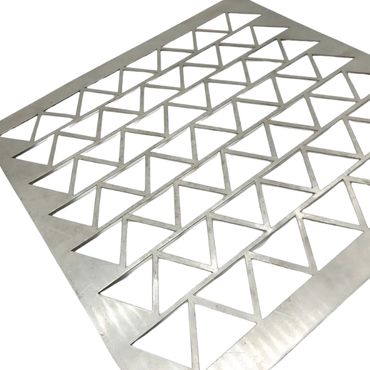

Triangular Hole Perforated Titanium Sheet features in solid structure.

Main Data:

- Uses: noise barriers, building façade, decoration

- Surface Treatment: Powder-Coated, Galvanized, Polished, Mill

Diamond Hole Perforated Titanium Sheet designed with diamond shape style.

Main Data:

- Feature: Practical & Durable

- Uses: Chemical Machinery, Shipbuilding, etc.

- Thickness: 0.5mm, customize

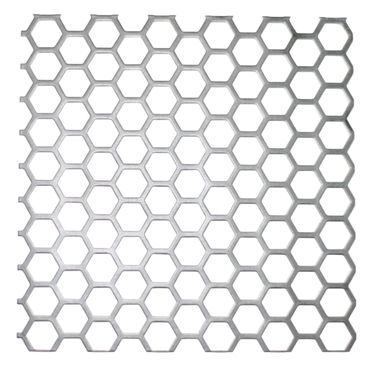

We supply high grade Hexagonal Hole Perforated Titanium Sheet to solve your sourcing need.

Main Data:

- Punching Type: CNC & Conventional

- Thickness: 10-100mm, customize

- Fine Hole Diameter: 0.4mm to 2mm

Why Choose XIONGQIAN

- Xiongqian supplies a wide range of perforated titanium sheets at a very competitive price.

- We are equipped with cutting-edge production machinery for welding, forming, punching, cutting, and finishing.

- Our engineering team carefully chooses the highest quality materials to ensure high-quality sheets. It involves selecting the proper grade and thickness.

- Our perforated titanium sheets are manufactured in accordance with ISO management system.

Perforated Titanium Sheet Quality Control

Your Perforated Titanium Sheet will bear stronger load and more durable even in outside conditions. We process it with A+ grade material and international brand production equipment line to meet industry standard.

We check each Perforated Titanium panel hole and more details for customer before delivery. There are professional testing tools in our factory and our QC staff inspect the chemical elements proportion to ensure it meets your rerquirement.

Related Products

What is Perforated Titanium Sheet

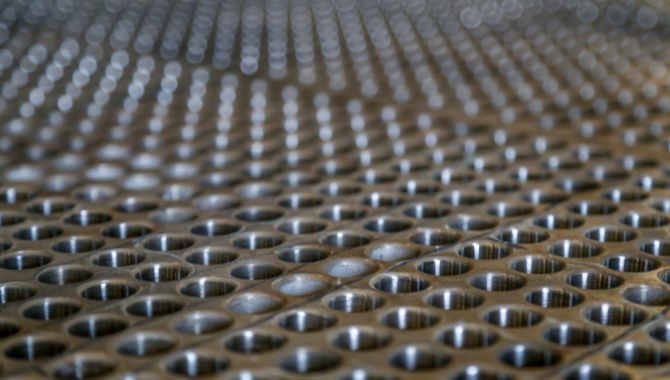

The punched titanium plate is made of pure titanium plate or titanium alloy plate as raw material, stamped by a mold, and processed by CNC punching. Hole pattern supports customization.

Perforated titanium plates are often used to manufacture chemical titanium filter plates, seawater filters, and titanium mesh filter elements due to their light weight, high strength, and strong corrosion resistance.

What is Perforated Titanium Sheet Size

The common Perforated Titanium Sheet is 1000*2000mm,1220*2440mm,1250*2500mm, thickness is 0.2mm – 3mm with hole size 0.8mm – 50mm.

What Factors Impacting Perforated Titanium Sheet Price

The factors that affect the price of perforated titanium plates are: alloy composition, processing method, mechanical properties and supply status.

What is Perforated Titanium Sheet Material

Pure titanium plate and alloy titanium plate

Suitable Application of Perforated Titanium Sheet

- Chemical Processing

- Desalination

- Power Generation Tools

- Pump and Valve Parts

- Prosthetic Devices

- Marine Hardware

- Decoration

- Screens

- Ceiling

- Curtain Wall

- Ventilation, etc.

Available Titanium Grade for Perforated Sheet

Titanium Alpha Alloy

It contains tin, aluminum, and other elements. This type of titanium can’t be strengthened through heat treatment but can be weldable. It is more creep-resistant than beta alloys.

Titanium Beta Alloy

Beta alloys are among the smallest category of titanium. They have excellent hardenability and cold formability. Compared to other titanium alloys, the beta alloy is heavier, having a 4840 kg/m 3 to 5060 kg/m 3 density range, and 1345MPA yield strength. This alloy can also be weldable.

Titanium Alpha-Beta Alloy

Unlike alpha alloy, the alpha-beta alloy can be strengthened through aging and heat treatment. This means that it can go through fabricating while it is still malleable. The perforated sheet made of this alloy is ideally suited for aircraft parts, marine hardware, chemical processing tools, and prosthetic devices.

Perforated Titanium Sheet Production

Perforated titanium sheets are also named punched metal. They are the most flexible and famous metal in mesh production. We manufactured them from the coils or sheets of metals, then we punched them uniformly using CNC technology.

Different patterns of titanium perforated sheets can be available using various molds. We can adjust its thickness based on your specifications. Xiongqian can also form or shear perforated titanium sheets to your desired shape and any requirements.

Perforated Titanium Sheet Specifications

| Thickness | Ranging from 0.3mm to 10.0mm |

| Available Surface Treatment | Painting, Powder Coating, Standard |

| Width | Minimum 1600mm |

| Length | Customized sheets or coil |

| Size Availability | 2000mm x 1000mm, 2440mm x 1220mm, 3000mm x 1500mm, 2000mm x 2000mm, customize |

| Hardness | Spring Hard, Quarter Hard, Half Hard, Hard, Soft |

Perforated Titanium Sheet Chemical Composition

| Ti | Min. 99.2 |

| C | Max. 0.1 |

| Fe | Max. 0.3 |

| H | Max. 0.015 |

| N | Max. 0.03 |

| O | Max. 0.25 |

Perforated Titanium Sheet Mechanical Properties

| Density (g/cm3) | 4.5 |

| Melting Point (°C) | 1665 |

| Tensile Strength | 49900 PSI, 344MPA |

| 0.2% Offset Yield Strength | 39900 PSI, 275MPA |

| Elongation (%) | 20 |

Perforated Titanium Sheet Equivalent Grade

- Standard: Titanium Gr.2

- WERKSTOFF NR: 7035

- UNS: R50400

Key Benefits of Perforated Titanium Sheet

- Excellent performance at 1200°C temperatures.

- High nickel content for excellent corrosion resistance

- High-strength and durable

- Resist high temperature

- Can withstand spalling and oxidation at more than 1260°C temperature

- Bright Finish

- Low weight