XIONGQIAN Perforated Zinc Sheet

Perforated zinc sheets are known to have small holes drilled into them. They are commonly used to make decorative accents and architectural details. Also comes with highly corrosion-resistant properties, making it the best material for outdoor use.

Your business will go fast with our perforated zinc sheet. We can tailor the size and design per your requirement. We can also process Perforated Titanium Sheet, Perforated Aluminum Sheet and more types.

Here at XIONGQIAN, we made these zinc sheets easier to install. They are perfect for any application, ranging from roofing to cladding. If you need them for your specific projects, contact us today!

Various Perforated Zinc Sheet for Wholesale

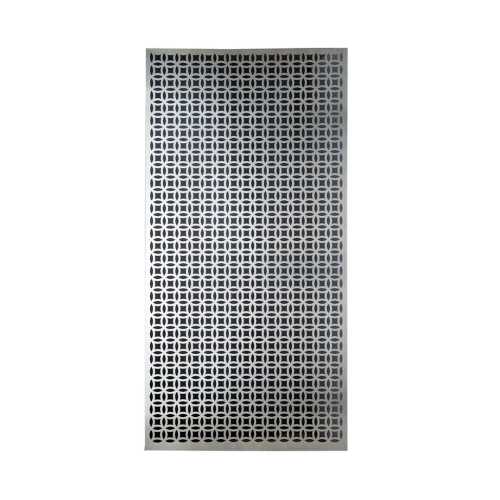

Comes with various hole sizes, shapes, and patterns punched through the metal. It is commonly found in industrial and commercial settings.

Widely used for decorative and architectural projects. It is made of zinc, which is a durable metal. Known for their extremely corrosion-resistant properties.

A material designed with small holes that provide ventilation and drainage. It is lightweight, yet strong and durable. Ideal for both indoor and outdoor use.

Zinc sheet that has been perforated with trapezoidal patterns. It offers multiple advantages, like corrosion resistance, high durability, and ease of maintenance.

The expanded zinc sheet comes with a zinc coating that provides extra strength and durability. It is lightweight but extremely strong and corrosion-resistant.

A durable and corrosion-resistant sheet material made from zinc. It is resistant to rust, weather, and chemicals. And can be used for ventilation, filtration, etc.

Slotted zinc sheet is pre-punched with slots series. It is used for filtration uses, drainage, and airflow control. Also used as a decorative material in architecture.

Perforated with square-shaped holes. It is often used in construction, engineering, and manufacturing applications. Popular for their strength and durability.

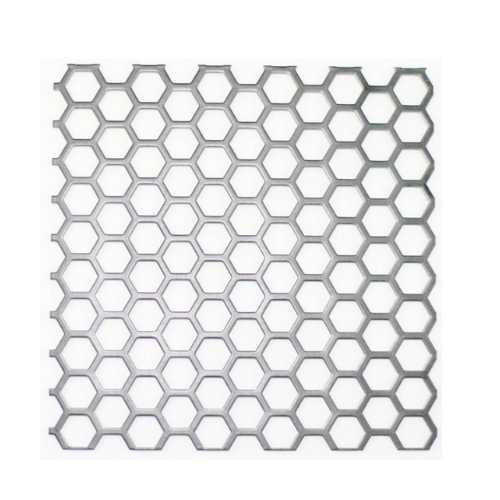

Featuring small round holes punched out of it. They are used in industrial and commercial applications such as air filters, air ducts, sound absorption, etc.

Why Choose XIONGQIAN Perforated Zinc Sheet

Our perforated zinc sheet is an excellent choice for businesses because it is strong, durable, and corrosion-resistant. It also has a uniform finish that is aesthetically pleasing. Therefore it will provide a professional look for any business.

In addition, the sheet is cost-effective and easy to install. Making it perfect for businesses looking for a reliable yet affordable material!

Related Products

Available in Different Metal Options

Here are the following metals we can use in manufacturing perforated zinc sheets.

- Cold rolled steel

- Galvanized steel

- Aluminum

- Stainless steel

- Copper

- Brass

- Zinc

- Pre-painted steel

- Pre-coated steel

- Polyvinyl chloride (PVC)

Step-by-Step Production Process of Perforated Zinc Sheet

- First, we will clean the zinc sheet surface to be perforated. We ensure no dirt or dust particles are present.

- We will then mark and measure the area that needs to be perforated on the sheet.

- Setting up a press with the appropriate die for your ideal perforated hole sizes and shapes.

- We will place the zinc sheet in the press. It presses the die into the sheet to create the perforated holes.

- After that, we make sure the holes are accurate.

- We clean the sheet again to ensure no debris is present.

- Once cleaned, we will apply any desired finishing touches, such as painting or coating the sheets.

- Finally, the sheet is ready for shipping or storage.

Standard Sizes Options of Perforated Zinc Sheet

The standard sizes of perforated zinc sheets are:

- 24 gauge: 0.0239”

- 22 gauge: 0.0299”

- 20 gauge: 0.0359”

- 18 gauge: 0.0478”

- 16 gauge: 0.0598”

- 14 gauge: 0.0747”

- 12 gauge: 0.1046”

- 10 gauge: 0.1345”

- 8 gauge: 0.1644”

- 7 gauge: 0.1874”

- 6 gauge: 0.2242”

- 4 gauge: 0.3033”

- 3 gauge: 0.3164”

- 2 gauge: 0.3543”

- 1 gauge: 0.4096”

List of Coatings Selection for Perforated Zinc Sheet

Hot-dipped galvanized. The process of submerging the zinc sheet into a molten zinc bath. It will create a uniform and durable coating, thus protecting the sheet from corrosion.

Electro-galvanized. An electrochemical process that deposits zinc coating on the sheet.

Zinc-coated. A process that involves rolling zinc onto the sheet to create a uniform coating.

Galvannealed. It involves the application of a zinc layer and iron alloy to the sheet. This contributes to corrosion protection.

Pre-painted/powder-coated. Involves the application of colored paint or powder to the sheet. This is for decorative purposes.

Anodized coating. An electrochemical process that creates an aluminum oxide layer on the sheet.

Fully Certified Perforated Zinc Sheets

We make sure all sheets meet complete standards and certifications. These include:

- UL Certification

- ASTM Certification

- CSA Certification

- ISO 9001 Certification

- NSF Certification

- NSF/ANSI 61 Certification

- RoHS Compliance Certification

- EN 10204-3.1 Certification

- ISO 14001 Certification

- NFPA Certification

FAQ about Perforated Zinc Sheet

How long will the perforated zinc sheet last?

The sheet can last up to 30 years or more, depending on the environment and how it is maintained.

What inspections do you perform to ensure its quality?

- Visual Inspection: Check for any corrosion signs, rust, or any other damage.

- Measurement Inspection: Measure the sheet thickness to ensure that it meets the required specifications.

- Hardness Test: Determines the material strength and durability.

- Stress Test: Measures the sheet’s ability to withstand various loads and pressures.

- Coating Test: Checking for any tear and wear signs to the sheet coating.

- Environmental Test: Test the sheet in various environmental conditions to ensure it can withstand the elements.

How do you ensure zero defect perforated sheets?

The best way to ensure zero defect perforated sheets is to use quality materials and maintain workmanship high standards.

We carried out regular inspections to check for any defects. Additionally, we used advanced technology to help minimize defects.

Finally, we used a professional perforator that has a good reputation to help ensure quality perforated zinc sheets.