XIONGQIAN Perforated Brass Sheet

A perforated brass sheet is a metal sheet with a perforated hole design. Made from a strong and durable alloy of copper and zinc, which gives it excellent corrosion and wear resistance. Brass has a high–end, luxurious look, making it a great choice for decorative purposes.

Your sourcing work for brass perforated metal sheet will become more easy with our strong technical support and fabrication. We can process various material such as Perforated Galvanized Sheet, Perforated Steel Sheet and more to help you save time to import from China.

XIONGQIAN is a professional perforated brass sheet manufacturer. We have thousands of various patterns accessible for your projects. Our team can custom cut, shape, and form perforated brass sheets suitable for a wide range of applications. Message us immediately!

Source Perforated Brass Sheet By Shape

Perforated brass sheet types with round holes which are punched in a straight line across the sheet.

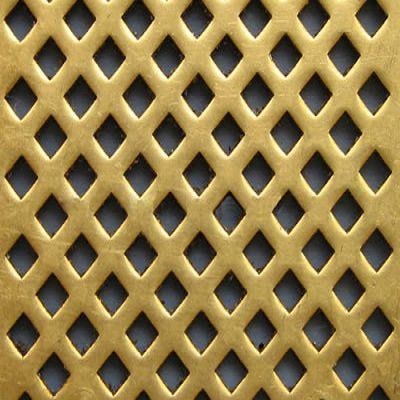

Small diamond–shaped holes are punched into the metal sheets. The diamond-shaped holes allow for greater airflow and ventilation.

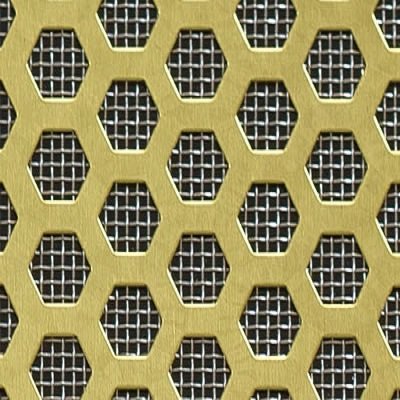

Perforated brass sheet with hexagonal holes. Known for its durability, malleability, and corrosion resistance.

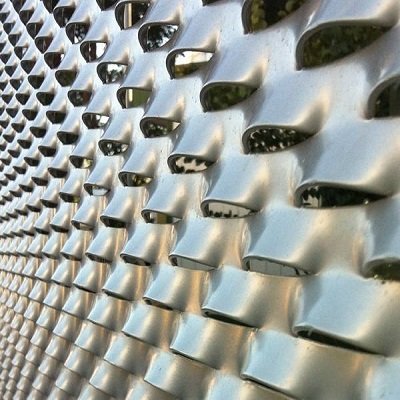

Louvered holes perforated sheet punched in a series of “V” shaped slots to create a series of slats.

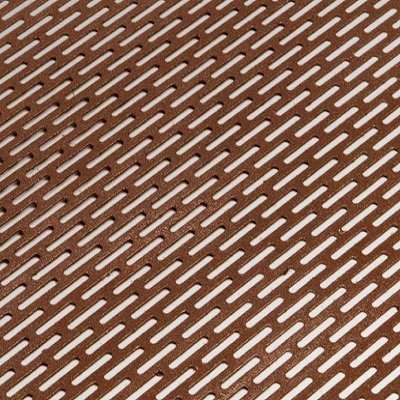

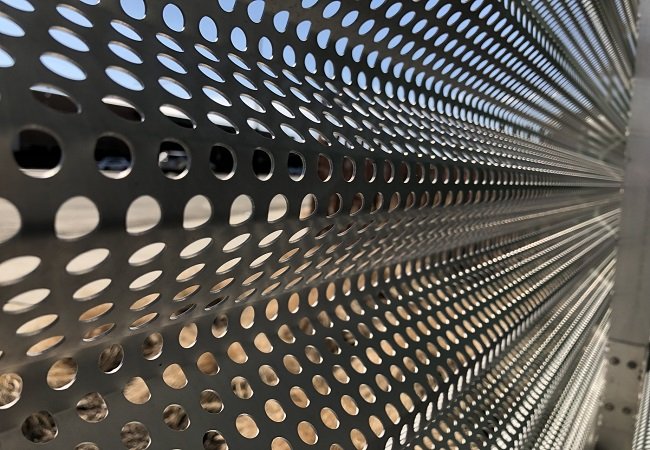

Punched with oblong holes. The holes are typically elongated in shape, with two short parallel sides and two long parallel sides.

The holes are shell-shaped and arranged in a uniform pattern. These are used for decorative elements or to allow air or liquids to pass through them.

Slotted holes brass perforated sheet is punched in a linear pattern to create a long, thin opening. Widely used for screening, soundproofing, and even filtration.

Brass perforated sheet with square–shaped holes punched into it. The holes can be of any size and are usually arranged in a regular pattern.

Sheet of metal with a pattern of small, regularly–spaced holes punched into it. Holes are staggered in a pattern, which creates a more open area.

WHY CHOOSE US

If you’re looking for a versatile and decorative perforated brass sheet used for a variety of applications, from architectural and industrial to decorative and ornamental, XIONGQIAN is the right supplier you can trust on.

- Manufacturing Process – We follow the same process as for any other sheet metal product. This includes cutting, forming, welding, and finishing.

- Quality Control – XIONGQIAN uses quality control measures to ensure that the perforated brass sheet is of the highest possible quality. This includes inspecting the sheet metal prior to production and after production.

- Material Specifications – Our team ensures that the highest quality materials are used to make the perforated brass sheet. This includes selecting the appropriate grade of metal, the right thickness, and the type of perforation.

- Health and Safety – We ensure that all safety measures are followed during the manufacturing process. This includes wearing personal protective equipment, following all safety regulations, and ensuring that all machinery is in good working order.

- Final Product – The final product meets all customer requirements. This includes providing the correct size, shape, and quantity of perforated brass sheets.

Related Products

Perforated Brass Sheet Sizes

- Standard hole size – 0.020″ to 1.00″

- Standard length – 4 feet (48”) by 8 feet (96”)

- Width – 0.25” to 36”

- Thickness – 0.010” (0.254mm) to 0.125” (3.175mm)

Benefits and Advantages of Perforated Brass Sheet Metal

- Perforated brass sheets are resistant to corrosion and rust, making them a highly durable material.

- They are lightweight yet strong, making them easy to work with and install.

- Perforated brass sheets have a high thermal and electrical conductivity, making them suitable for use in various electrical and engineering applications.

- The perforated openings can be customized to any shape and size, allowing for greater flexibility when it comes to design.

- Brass is a non-magnetic material, which makes it suitable for use in applications where magnetic materials are not suitable.

- Perforated brass sheets are easy to clean and maintain.

- They are available in a variety of finishes, making them suitable for use in different applications.

Perforated Brass Sheet Grades

XIONGQIAN works with various brass grade types in perforated brass sheet manufacturing. Below are some of the followings:

- C26000 Cartridge Brass

- C27000 Yellow Brass

- C36000 Free-Cutting Brass

- C46400 Naval Brass

- C48200 Semi-Red Brass

- C68700 Architectural Brass

- C71500 Copper-Zinc-Lead Alloy (Leaded Brass)

- C83600 Free-Machining Brass

Wide Range of Surface Treatments

Perforated brass sheet is available in a variety of finishes allowing it to be used in both interior and exterior applications. Some are the following surface coatings we offer:

- Anodizing: Anodizing is a process that creates an oxide layer on the surface of the brass sheet. This layer is corrosion-resistant and can be used for decorative purposes. It can also increase the durability of the brass sheet and provide protection against environmental wear and tear.

- Polishing: Polishing is a process used to give brass sheets a smooth, lustrous finish. This finish can be used for decorative purposes, or to increase the corrosion resistance of the brass sheet.

- Plating: Plating is a process used to deposit a metal coating onto the surface of the brass sheet. This coating can be used for decorative purposes, or to increase the durability of the brass sheet. Common plating materials used for brass sheets include nickel, chrome, gold, and silver.

- Brushing: Brushing is a process used to create a textured finish on the surface of the brass sheet. This finish can be used for decorative purposes, or to increase the corrosion resistance of the brass sheet.

- Patination: Patination is a popular surface treatment for perforated brass sheets because it helps to protect the material from corrosion and discoloration, while also creating an attractive, decorative finish.

Perforated Brass Sheet Applications

- Filtration: Perforated brass sheets are often used in a variety of filtration applications, such as air and water filtration, thanks to their ability to filter out particles and debris.

- Decoration: The decorative, ornamental look of perforated brass sheets makes them a popular choice for architectural and interior designs.

- Acoustic Diffusers: Perforated brass sheets are often used as acoustic diffusers in recording studios and concert venues, as their perforation allows sound to be diffused evenly.

- Screening: The perforated holes of brass sheets make them ideal for screening and sifting applications, such as in food processing and other industrial processes.

- HVAC: Perforated brass sheets are often used as air diffusers in HVAC systems, allowing air to flow evenly throughout the system.

FAQ of Brass Perforated Sheet

What to consider in buying perforated brass sheets?

- Grade of brass used.

- Size, shape, and thickness of the sheet.

- The pattern of the perforations and the size of the holes.

- Type of finish, such as polished, brushed or anodized.

- Type of adhesive used, if any.

- Cost of the sheet.

- Availability of other materials, such as aluminum or stainless steel, for the same application.

Is perforated brass sheet non-flammable?

No, the perforated brass sheet is not non-flammable. The perforated brass sheet has a low melting point and is flammable.

What is the formula for calculating perforated brass sheet weight?

To calculate the weight of a perforated brass sheet, you need to know the thickness and size of the sheet, as well as the weight density of the brass. Once you have this information, you can use the following formula to calculate the weight: Weight (lbs) = Thickness (in) x Width (in) x Length (in) x Weight density (lbs/in³) of brass.

How much is the perforated brass sheet price range?

The price of perforated brass sheets depends on the size, thickness, pattern, and quantity. For example, a 0.125” thick sheet of 24” x 48” perforated brass sheet with a round hole pattern may range from $40 to $80 per sheet. A 0.063” thick sheet of 36” x 48” perforated brass sheet with a square hole pattern may range from $30 to $60 per sheet.