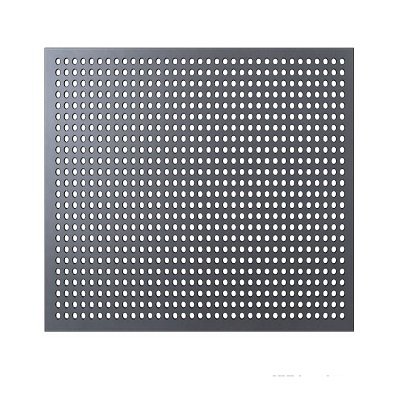

XIONGQIAN Perforated Galvanized Sheet

Perforated steel sheet is often galvanized for increased corrosion resistance. Galvanizing is a process that involves coating the steel sheet with a thin layer of zinc. The zinc acts as a barrier, protecting the steel from corrosion and oxidation. The added corrosion resistance makes galvanized perforated steel sheets an ideal choice for outdoor applications, such as stair treads, fence panels, and protective grates.

The perforated design of the sheet allows for air, sound, and liquid to pass through, making them perfect for ventilation systems, acoustic baffles, and filtration systems. They can also be used to create decorative features, such as increasing the privacy of a space or accenting the look of a building or home.

At XIONGQIAN, we design high-quality and durable perforated sheets for projects and industries. We have the complete capabilities to manufacture perforated galvanized sheets, perforated aluminum sheet, perforated steel sheet and more perforated sheet according to your specifications. Please get in touch with us for more information.

Perforated Galvanized Sheet By Different Materials

Perforated galvanized steel sheets are extremely durable and resistant to rust, corrosion, etc. This sheet is easy to install and maintain.

Perforated galvanized aluminum sheet designs allow for air and light to flow through, making them ideal for a variety of applications including industrial, agricultural, and residential settings.

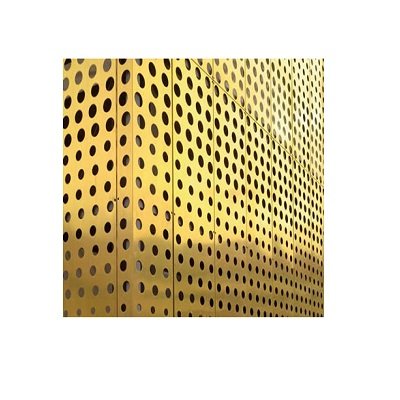

Made from a combination of galvanized steel and copper, resulting in a sturdy and rust-resistant product. This type of sheet is ideal for a variety of applications, such as fencing screens, decorative panels, and acoustic panels.

Perforated galvanized stainless steel sheets are great for air and light filtration, as well as for use in HVAC systems. The sheets can be easily cut or shaped to fit any need.

Strong and durable sheets of zinc-coated steel that have been punched with a pattern of holes. The zinc coating prevents corrosion and increases the longevity of the sheet.

Perforated galvanized brass sheet is a thin sheet of brass metal with perforated holes in it. The perforations can be of various shapes such as round, square, rectangular, triangular, or any other custom shape.

Why Trust QIONGXIAN Perforated Galvanized Sheet

QIONGXIAN is a leading manufacturer of perforated galvanized sheets and other metal products. We offer a wide selection of perforated and wire mesh metal products, excellent customer service, and competitive prices. All products we produce are made from high-quality materials and are designed to last. Additionally, QIONGXIAN offers custom manufacturing services to ensure that customers can get exactly what they need for their projects. Message us!

Related Products

How Perforated Galvanized Sheet Is Made

A perforated galvanized sheet is made by taking a sheet of galvanized steel and punching it with a machine that creates regular holes. The size and shape of the holes can vary depending on the application. The sheet is then cut to the desired size. If the sheet is to be used outdoors, it is usually painted or coated to protect it from rust and other elements.

Specifications of Perforated Galvanized Sheet

- Material grade – The most commonly used grade for perforated sheets is G90 (0.90 ounces per square foot). This is a zinc-coated galvanized steel. Other galvanized steel grades include G60 (0.60 ounces per square foot) and G40 (0.40 ounces per square foot).

- Hole patterns – The most common hole patterns for perforated galvanized sheets are round, square, slotted, and hexagonal. Other available designs include triangular, diamond, and decorative.

- Spangle types – The types are regular spangle, small spangle, big spangle, and zero spangles. Regular spangle is the most common type, and the other three types are variations of the regular spangle.

- Thickness – Typically, perforated galvanized sheets are available in thicknesses ranging from 24 gauge (0.024 inches or 0.6 mm thick) to 10 gauge (0.134 inches or 3.4 mm thick).

- Hole sizes – Perforated galvanized sheet comes in a wide range of hole sizes, ranging from small 1/8-inch holes up to large 3-inch holes.

- Width – up to 1600mm, customized

- Length – 1000-12000mm, customized sheets.

Perforated Galvanized Sheets Available Finishes

Perforated galvanized sheet metal is available in many different finishes, including mill finish, pre-galvanized, hot-dip galvanized, powder coated, and anodized. Each finish has its own unique properties and applications.

- Mill-finish galvanized sheet metal is the most basic and least expensive option, but it is often not the most attractive or durable choice for many applications.

- Pre-galvanized sheet metal is a galvanized sheet that has been coated with a special layer of zinc before being punched.

- Hot-dip galvanized sheet metal is typically used for outdoor applications and is much more durable than pre-galvanized.

- Powder-coated galvanized sheet metal is a type of coating that is applied as a dry powder, typically electrostatically, and then cured with heat.

- Anodized galvanized sheet metal has a thin layer of aluminum oxide applied to the metal surface, which helps to protect it from corrosion and wear.

Perforated Galvanized Steel Sheet Properties

The properties of perforated galvanized steel sheet are as follows:

- Strength: Perforated galvanized steel sheet is solid and durable, able to withstand heavy loads.

- Corrosion Resistance: The zinc coating on the surface of the sheet provides excellent protection against corrosion.

- Easy Installation: The perforations allow for easy installation of the sheet, making it ideal for use in a range of applications.

- Aesthetics: The galvanizing process gives the sheet a smooth, shiny finish that is visually appealing.

- Cost: Perforated galvanized steel sheet is relatively inexpensive compared to other types of steel sheet.

Wide Applications of Perforated Galvanized Sheet

Perforated galvanized steel sheet is used in a range of applications, from industrial to residential. It is often used for industrial purposes such as filtration, soundproofing, and air conditioning. Moreover, this sheet is used in residential settings as a decorative element on walls, ceilings, privacy screens, vents, and fences. These may be found in automotive applications such as grilles, bumpers, and wheel wells.

FAQ of Perforated Galvanized Sheet

How do you custom-perforate galvanized sheets?

Choose the type of perforation you want for your galvanized sheet. Options include round holes, square holes, and slotted. Determine the size of the holes you want. Choose the spacing between the holes, and the thickness of the sheet material. Lastly, you can place your order.

How do you ensure perforated galvanized sheet quality assurance?

XIONGQIAN ensure quality assurance of perforated galvanized sheet through a combination of rigorous quality control processes. These processes may include using high-quality raw materials, conducting regular inspections of the finished product, and testing the galvanized sheet for durability, strength, and corrosion resistance. Additionally, our team follows all applicable industry standards and regulations in order to ensure the highest quality of the product.

Name some of the perforated galvanized sheet quality certifications

The quality of perforated galvanized sheets can be verified by checking for certifications from the American Galvanizers Association (AGA), the Underwriters Laboratories (UL), and the International Code Council (ICC). The most common certifications for galvanized steel are ASTM A653, ASTM A929, and ASTM A1046. These standards ensure that the product meets the requirements for corrosion resistance and mechanical properties. Additionally, XIONGQIAN provides its own quality assurance and testing protocols to ensure perforated galvanized sheets meet the highest standards.

How to choose the best material for perforated metals?

- Application: The first step in selecting the best material for perforated metals is to consider the application. Different applications require different materials. For example, if you are using perforated metal for decorative purposes, you may want to choose a material that is aesthetically appealing. If you are using metal for structural purposes, you may want to opt for a more robust material such as stainless steel or aluminum.

- Durability: Another important factor to consider when choosing the best material for perforated metals is durability. Typically, metals such as stainless steel and aluminum are the most durable and can withstand extreme temperatures and weather conditions.

- Cost: In addition to durability, the cost is also an important factor to consider when choosing the best material for perforated metals. Some materials may be more expensive than others, thus, you need to consider the budget before purchasing.

- Consider the Environment: Finally, it is important to consider the environmental impact of any material you choose. Some materials, such as stainless steel, are considered to be more environmentally friendly than others.

What is the price range of this Perforated Galvanized Sheet?

The price range is typically between $30 and $100 per square foot.