XIONGQIAN Metal Windbreak Fence

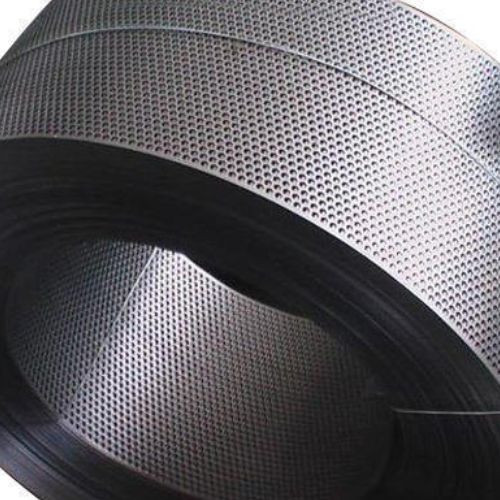

Windbreak fence is a kind of metal wall with different combinations of holesused to weaken the strength of the wind and suppress the flying of dust. It ismainly formed by using raw materials through mold punching, pressing andspraying.

The principle is that it can make the strong wind appear thephenomenon of adsorption and separation, greatly reducing the speed of airflow, thus reducing the air flow to the surface of the pile of materials, so as toachieve the effect of dust suppression.

Mainly divided into single-peak type,double-peak type, three-peak type, color steel tile windproof dust suppressionnetwork.

Different Types of Windbreak Fence

Why Choose XIONGQIAN

- XIONGQIAN is an experienced manufacturer, with rich experience in metal windbreaks production.

- We have a dedicated team of professionals who provide quick service and technical support.

- Our company offers a wide range of products, from standard windbreaks to customized designs.

- You can obtain excellent quality products at competitive prices.

- XIONGQIAN has a wide network of suppliers and distributors throughout China, ensuring quick delivery and reliable service.

Related Products

XIONGQIAN Metal Windbreaks Fabrication

Design – The first step in the process is designing the windbreak. Our design team will create a detailed plan for the product and make sure it meets the needs of the customer.

Material Selection – The next step is to choose the right material for the windbreak. The metal material needs to be strong and durable and able to withstand the elements.

Fabrication – After the design and material selection is complete, the windbreak can be fabricated. This process involves cutting, forming, and welding the material into the desired shape and size.

Finishing – The windbreak then needs to be finished with paint or powder coating. This will protect the product from corrosion and wear and tear.

Testing – The final step is testing the windbreak. This includes testing the strength and durability of the product and making sure it meets the customer’s requirements.

Suitable Metal Windbreak Materials

- Aluminum: Aluminum is lightweight, durable, and corrosion-resistant, making it a great material for windbreaks. It is also easy to install and maintain, making it a popular choice for windbreaks.

- Steel: Steel is available in a variety of different thicknesses and sizes, allowing you to choose the right size for your needs.

- Galvanized Steel: Galvanized steel is a long-lasting material that can withstand harsh weather conditions. It is also corrosion-resistant, making it an ideal material for windbreaks.

- Stainless Steel: Stainless steel is a popular choice for windbreaks due to its strength and corrosion resistance.

Extensive Surface Treatments Available

XIONGQIAN offers different types of metal surface treatments for improved corrosion resistance and appearance.

- Galvanized Steel Coating

- Powder Coating

- Anodizing

- Zinc Rich Primer Coating

- Fluoropolymer Coating

- Sand Blasting

- Fluoropolymer Paint

- Enamels

- Polyurethane Coatings

- Epoxy Coatings

Metal Windbreak Applications

- Reduce wind erosion and protect crops, gardens, and other areas from wind damage.

- Installed around livestock enclosures to reduce wind exposure and provide more comfortable living conditions for animals.

- Used to direct wind away from buildings, roads, and other sensitive areas, providing a buffer from wind-blown dust, debris, and other materials.

- Protect outdoor seating areas from wind, allowing people to enjoy a more comfortable outdoor experience.

- Reduce wind noise, providing a more peaceful and relaxing outdoor environment.

- Used to create shady areas and provide shelter from the sun, making outdoor areas more enjoyable.

- Improve the efficiency of cooling systems, helping buildings and vehicles to stay cooler in hot weather.

Metal Windbreak Advantages

Durability

Metal windbreaks are incredibly durable and can withstand extreme weather conditions. They are also resistant to damage from ultraviolet rays, meaning they will last for many years.

Low Maintenance

Metal windbreaks require little maintenance and do not need to be painted or stained, unlike wood or other materials.

Cost

Our range of metal windbreaks is often cheaper than other materials and can be a cost-effective solution for wind protection.

Versatility

Windbreaks can be customized to fit any size or shape, making them a great choice for any outdoor space.

Environmentally Friendly

Metal windbreaks are made from recycled materials, which makes them an environmentally friendly option.

Metal Windbreak FAQ

What are metal windbreaks available colors?

Metal windbreaks are typically available in a range of neutral colors, including black, gray, and silver. We may also offer other colors, such as brown or white, depending on your requests.

How strong is a metal windbreak?

Metal windbreaks are designed to be very strong and durable, but their strength can vary depending on the size and the type of metal used.

How much is a metal windbreak?

The cost of a metal windbreak varies widely depending on the size, shape, and type of metal used. Generally, you can expect to pay anywhere from $200 to $2,500 for a metal windbreak.

How do you ensure quality metal windbreaks?

- Raw Material Inspection: Quality control begins with the inspection of raw materials used in the production of metal windbreaks. We inspect the material quality, size, and appearance of the raw materials against the standards before they are used in the production process.

- Quality Control During Production: During the production process, our team conducts quality checks at various stages to ensure that all components of the windbreaks are assembled correctly and meet the required standards of quality.

- Final Inspection: The finished product should undergo a thorough inspection before it is shipped out. This inspection includes measurements of the windbreak’s dimensions as well as a visual inspection to ensure that all components are properly attached and functioning correctly.