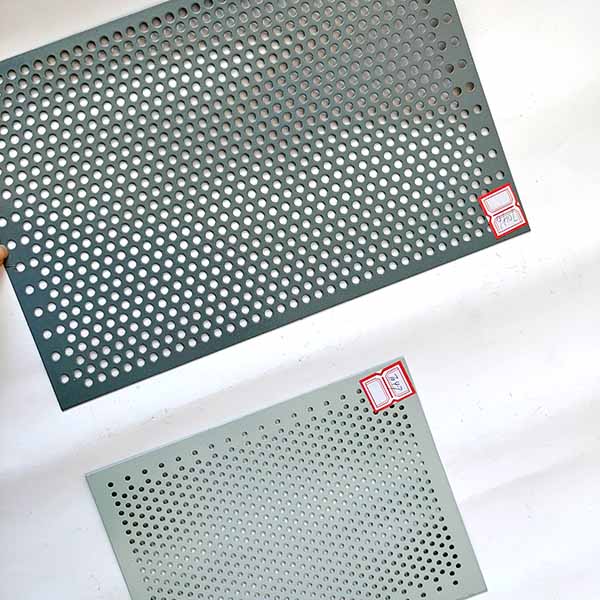

Round Hole Perforated Metal Application and Material

Round Hole Perforated Metal Application

Applications for round perforated sheets include:

Cladding and ceiling panels.

Sunshade and sunscreen.

Filter sheets for grain sieving, sandstone, kitchen garbage.

Decorative banister.

Protective fences of overpasses and machine equipment.

Balcony and balustrade panels.

Ventilation sheets, such as air condition grilles

While obtaining semi-private effects and security, the space still maintains comfortable breathability, and airflow, forming a wonderful light and shadow effect. Perforated fences and banisters keep people safe and enclosed machines and other properties away from damage.

Round Hole Perforated Metal Nickel Perforated Sheet

Applications: Chemical industry, energy sector, fuel cells, and electrolysis equipment.

Advantages: Resistant to acids and alkalis, as well as heat.

Alloy Perforated Sheets

Monel Alloy (Nickel-Copper Alloy)

Resistant to seawater corrosion, making it suitable for marine engineering applications.

Inconel (Nickel-Chromium-Iron Alloy)

High-temperature alloys are used in aerospace applications and gas turbines.

Aluminum-Magnesium Alloy

High-strength, lightweight, non-metallic perforated panels are commonly used in transportation, shipbuilding, and building facades.While metal is the primary material used, non-metallic sheets are occasionally employed.PVC plastic panels are lightweight, waterproof, and cost-effective, making them ideal for temporary partitions.Wooden perforated panels offer excellent decorative appeal and sound-absorbing properties, making them commonly used in indoor acoustic applications such as theaters and KTVs.

Round hole perforated metal production process

Raw Materials → Uncoiling → Leveling → Cutting → Hole Design → Punching → Deburring → Cleaning → Leveling and Shaping → Surface Treatment → Inspection → Packaging → Shipping