Round Hole Perforated Metal Be Used To

Round holes patterns can be used to:

Grind seed and spices

Separate rock or ore

Filter and control gas and fluids

Suppress noise in jet engines while allowing air flow

Filter air to keep electronic equipment clean and cool

Provide security in doors, windows and gates

Add creativity to store fixture displays

These are achieved with patterns with 12% to 67% and greater open area, but most patterns are 23% to 58% open area.

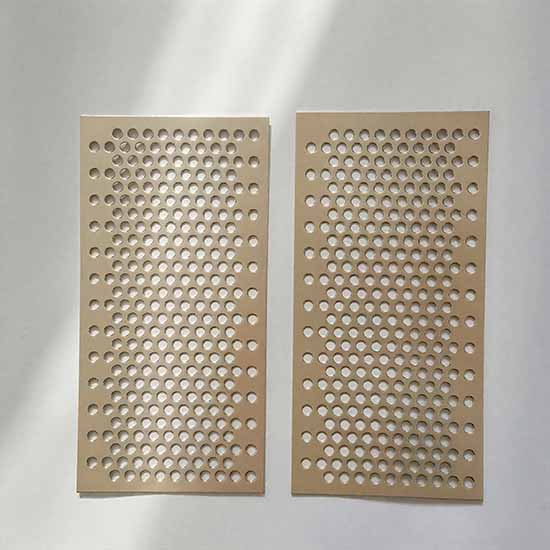

Round Hole Perforated Metals

Round hole patterns can be arranged in either staggered or straight-line formations. Staggered patterns offset the holes from each other, while straight-line patterns align the holes in parallel rows.

There are three types of edge margins available: finished, unfinished, and blank. Finished margins are clean and uniform, unfinished margins are incomplete at the sheet’s edge, and blank margins feature holes extending to the edge of the sheet.

Choosing a Pattern

The choice of pattern for perforated metal depends on its intended application. Options are available in both standard and custom designs, featuring various sizes, shapes, pitches, open area percentages, and hole arrangements.

Common perforation patterns include round holes, square holes, slotted holes, hexagonal holes, and decorative designs, each providing distinct acoustic, airflow, or structural properties.

Factors such as required mechanical strength, acoustic performance, ventilation, filtration efficiency, and decorative appearance all influence the final pattern and configuration.

Part of the selection process involves evaluating the size of the holes and the bars, which are the spaces between them. Achieving the optimal balance between hole size and bar width is crucial for the metal’s strength, rigidity, and suitability for its intended application. Larger holes require narrower bars and can provide greater airflow or light transmission but may compromise mechanical strength.

Generally, the thickness of the metal should not exceed the size of the holes or the width of the bars to prevent tool failure and maintain manufacturing efficiency during processing. Modern CAD software and computer-controlled machinery enable highly precise and repeatable custom patterns based on project-specific design criteria.

Surface Treatment

XIONGQIAN offers multiple surface treatment options for different commercial and industrial applications.

Spraying

Polishing

Anodizing

Galvanized

Powder coating

Ant-rust oil painting

PVDF coating

And more surface treatment.