Round hole perforated metal is a versatile and highly functional material used in various industrial, architectural, and commercial applications.

Known for its durability, strength, and aesthetic appeal, this type of perforated metal features uniformly spaced round holes that can be customized to suit specific needs.

Whether you’re looking to enhance airflow, provide filtration, add an element of design, or improve noise control, round hole perforated metal offers a solution that combines both form and function.

Uses and Applications

Round hole perforated metal products can be used for numerous functional and decorative purposes, including:

Separating ore or rock in mining applications

Security in windows, gates, and doors

Air filtration

Noise reduction

Enhancing the appearance of retail store displays

Various types of screens and vents

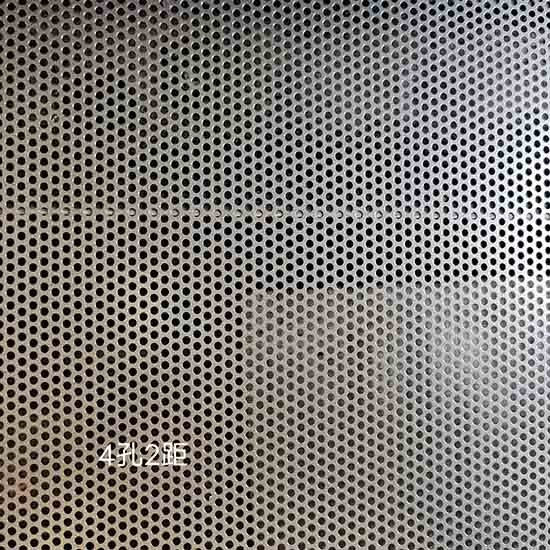

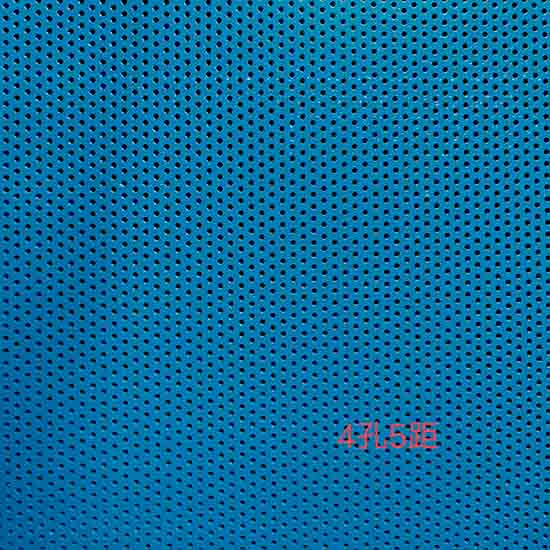

Steel Perforated Sheet

Perforated Steel Sheet is a sheet product that has been punched with a wide variety of hole sizes and patterns providing an aesthetic appeal.

Perforated Steel Sheet offers savings in weight, passage of light, liquid, sound and air, while providing a decorative or ornamental effect.

Perforated Steel Sheets are common in interior and exterior design along with many industrial applications including: displays, fixtures, furniture, security, sifting, machine guards, enclosures, infill panels, screens, filters, ventilation & more.

Metal wall panel systems are a trusted choice for commercial and industrial architects, contractors, and building owners seeking high-performance cladding solutions.

Our metal wall panel systems are highly customizable and designed to provide durable, aesthetically-appealing solutions with virtually endless design possibilities for all price points.

Product Definitions, Terms and Spec Information:

Perforated Metal

• Very versatile and functional depending on its shape opening and gauge and sixe

• Can be strong depending on gauge

• Can vent, screen and filter a variety of solids

• Is lightweight but durable

• Its openings can be chosen for optical requirements appealing to to variour architectural requirements

• Perforated Metal also helps to diffuse light and air. If manufacturing a product that needs to be lighter, for the right product application, use perforated metal — metal sheet retains a high percentage of it’s strength after it’s perforated but loses a lot of costly weight.

Important Terms for Perforated Metal:

• Perforations

• Round Perforations: Staggered (60 degree pattern) is standard.

• Variations include 45 degree staggered, and straight line pattern.

• Square Perforations: Staggered or straight line pattern.

• Slotted Perforations: Side staggered, end staggered, or straight lines.

• Slotted perforations will be round end slots; specify if square end slots are required.

• Other Perforations: Available upon request.

Spacing Perforations

Spacing for large perforations will be designated be either Centers of perforations, or by the Open Area required. Spacing for small perforations will be designated by either Centers, or Open Area, or if more practical, by the Number of Perforations to the Square Inch.

Pattern of Perforations

• Staggered Perforations, both Round & Square: Direction of the stagger will normally be the short dimension of the sheet. Straight row of hole is normally parallel to long dimension of sheet.

• Slotted Perforations: The long dimension of the slots can be furnished with either the width or length of the sheet in most cases.

Margins

• Perforated Stock Size Sheets & Plates: The long sides of the sheet will be supplied with minimum margins. The short sides of the sheet will have either minimum margins or no margins.

• Sheets & Plates Re-sheared after Perforating: Special margins are available to specifications but they must carry a tolerance within the limits of the perforating tool.