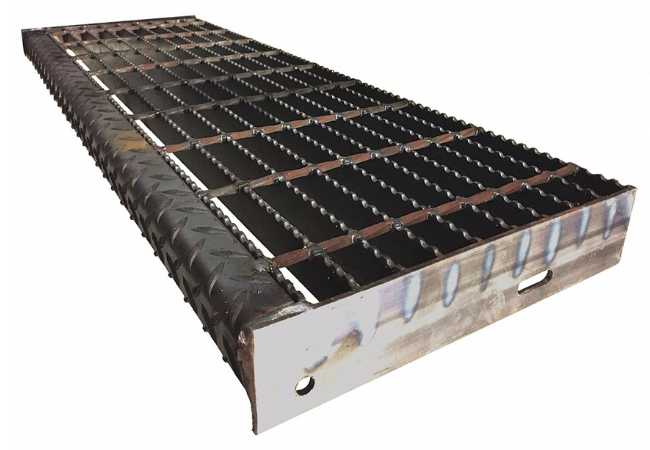

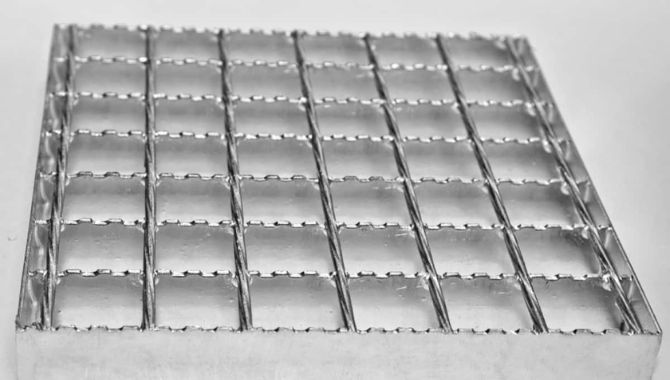

Serrated Grating

XIONGQIAN serrated grating is the perfect choice for any project where safety is the top priority. It is made from high-quality materials to fit your project’s needs. Material options include aluminum, carbon steel, and stainless steel. Contact us to learn more about how Serrated Grating can complete your project safely and in style.

- Bearing Bar Size: 25×5, 30×5, 32×5, 40×5, 50×5, 65×5, 75×6, etc.

- Bearing Bar Pitch: 5, 15, 22.5, 30, 30.16, 32.5, 34.3, 40, 41.25, etc.

- Cross Bar Size: 5×50, 6×50, 8×50, etc.

- Cross Bar Pitch: 50, 100, etc.

- Height: 15mm, 20mm, 25mm, 30mm, 40mm, etc.

- Width: 1000mm, 1200mm, 1500mm, etc.

- Length: 2000mm, 2400mm, 3000mm, etc.

Reliable Serrated Grating Manufacturer in China

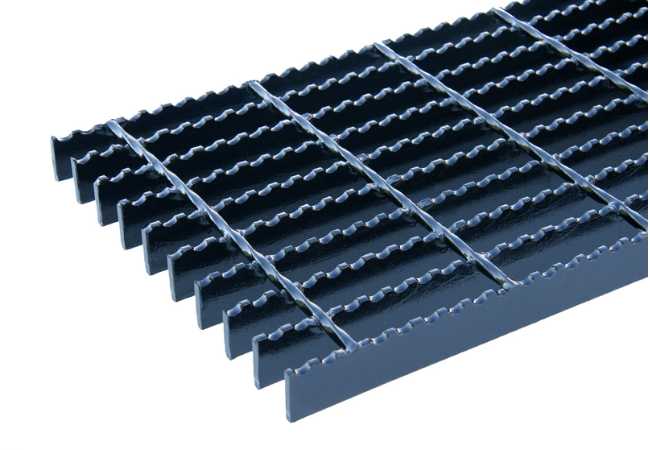

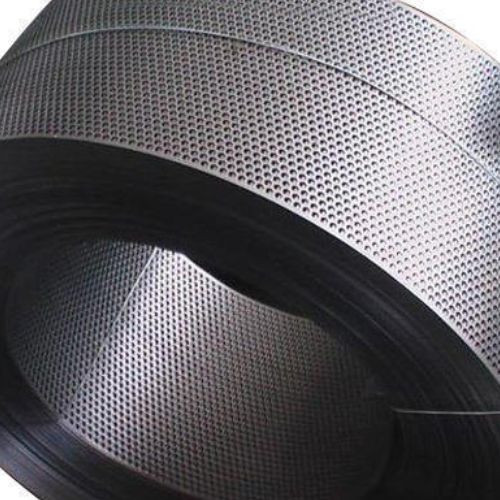

As the name implies, the serrated grating has a serrated bearing bar shape. We produced them by using a serrated blade. It cut metal into a series of small, uniform bars. The bars are then press-fitted together to form a grid-like pattern. The serrated grating is then galvanized for corrosive protection.

Depending on the application, the grating may be available in plain, painted, or galvanized finishes. We also offer different thicknesses and load-bearing capabilities. Additionally, the serrations may be available in different depths.

Request a quote today!

Why Choose XIONGQIAN Serrated Grating

The serrated grating has numerous advantages, including:

- Increased safety: The serrated surface of the grating provides increased traction. This helps to reduce the slips and falls risks. Also preventing accidents and injuries in the workplace.

- Easy installation: The grating is easy to install and requires minimal maintenance. This makes it a cost-effective solution for various industrial applications.

- Durability: It is resistant to corrosion, wear, and tear. Making it an excellent choice for long-term use.

The two most common types of serrated gratings are press-locked and swage-locked.

Press-locked grating is created by pressing the cross bars into the bearing bars. While swage-locked grating is formed by swaging the bearing bars and cross bars together.

The main difference between serrated and non-serrated gratings is the surface profile.

Non-serrated gratings usually have a smooth surface, while serrated gratings have a toothed or grooved surface. This difference gives serrated gratings improved slip-resistance and strength.

They last for many years, depending on their application and the environment in which it is used. In most cases, it will last 10-15 years with regular maintenance and cleaning.

Serrated grating is commonly used in commercial and industrial applications. It is often used as walkways, stair treads, decking, etc.

You can also find them in industrial plants, chemical plants, and oil & gas refineries. Or other areas where slip resistance and drainage are important. They are also used in architectural and interior design applications.