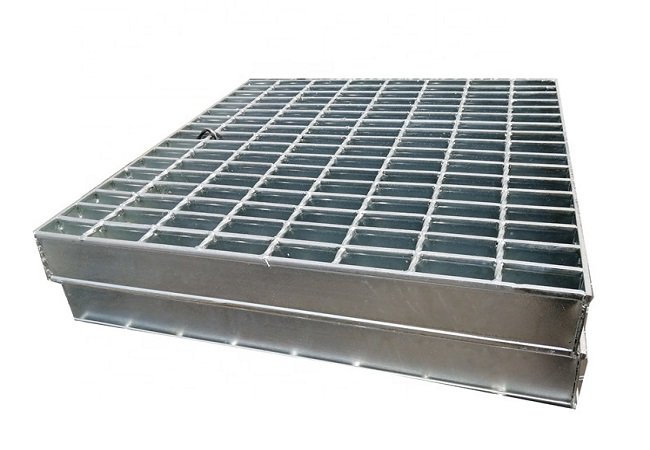

Galvanized Grating

The galvanized grating has a grid-like look. They are composed of twisted square bars and flat bars that have been vertically and horizontally welded. Also, they are sometimes called galvanized bar grating.

- Most popular and strongest type of grating

- Serrated and smooth top surfaces are available

- Surface treatment: electro-galvanization, hot-dipped galvanization, painting, etc.

- Available in a range of designs and sizes

Galvanized Grating Manufacturer

XIONGQIAN aims to provide quality galvanized metal gratings at reasonable prices. All of our galvanized metal gratings are made from high-quality iron, mild steel, or low-carbon steel. We also strictly implement quality control inspections during the whole manufacturing stage to guarantee their quality. Every galvanized metal grating we produced has met international quality standards.

To build long-term business relationships, we offer fast turnaround times, excellent customer support, and after-sales services.

If you want to learn more about our galvanized metal gratings or services, please contact us!

Types of Galvanized Gratings

We offer different types of galvanized gratings such as:

Press-Locked – This type of galvanized metal grating is commonly used in machinery factories, oil refineries, power plants, etc. It has a grid that is made by press-locking or welding the bearing bars to the cross bars.

Welded – The welded galvanized metal gratings have a surface that can be electro-galvanized or hot-dip galvanized. They are composed of I-bars and flat bars.

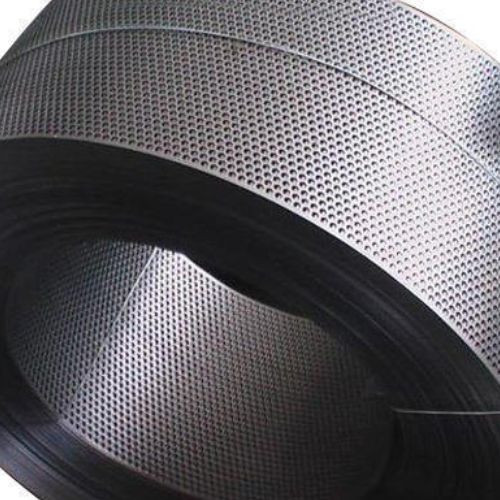

Hot-Dip Galvanized – The hot-dipped galvanized metal gratings have been immersed in a bath of molten zinc. The zinc enhances its hardness, adhesion, and corrosion resistance.

Electro-Galvanized – The electro-galvanized galvanized metal gratings are made by electroplating. They are bonded with a zinc layer for enhanced corrosion resistance.

Galvanized steel gratings are used for a variety of applications such as:

- Catwalks

- Fencing

- Decking

- Flooring

- Drainage pit cover

- Mezzanines

- Trench cover

- Stair tread

- Storage and wash rack

- Maintenance platform

- Ramps

- Dock

- Ventilation screens

- Machine safeguards

- Windows

- Guardrail

- Platforms

Our galvanized metal gratings offer the following features:

- beautiful appearance

- high load-bearing capacity

- easy to lift

- lightweight

- high strength and durable

- superior corrosion resistance

- long service life

- anti-theft design

- low maintenance

- excellent impact resistance

- chemical-resistant

- weather-resistant

The processes of manufacturing galvanized metal gratings include:

- Pre-Treatment

- Pickling

- Fluxing

- Galvanizing

- Cooling

- Passivation

- Packaging