XIONGQIAN Perforated Composite Panels

Perforated composite panels are a composite material often used in modern construction. It is a durable alternative to traditional materials such as wood, steel, and aluminum. In whatever applications require acoustic and visual privacy, our perforated composite panels are an excellent option.

XIONGQIAN provides perforated panels that are easy to install. Therefore can easily fit both interior and exterior installations. If you need them for your specific projects, we offer a wide variety of colors, textures, and finishes. It is also popssible for you to wholesale Perforated Aluminum Sheet and other Perforated Sheets from us.

Perforated Composite Panels For Wholesale

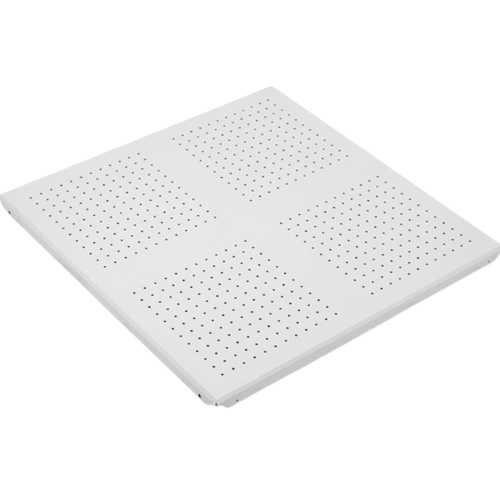

The acoustic panels are made of a perforated metal sheet with a noise-absorbing material behind it. The perforations allow sound waves to pass through the panel.

Type of paneling used in construction and other applications where building safety is a concern. Made of a special composite material that is fire-resistant.

A versatile building material made from two sheets of metal. These panels are lightweight, durable, and provide excellent insulation for various applications.

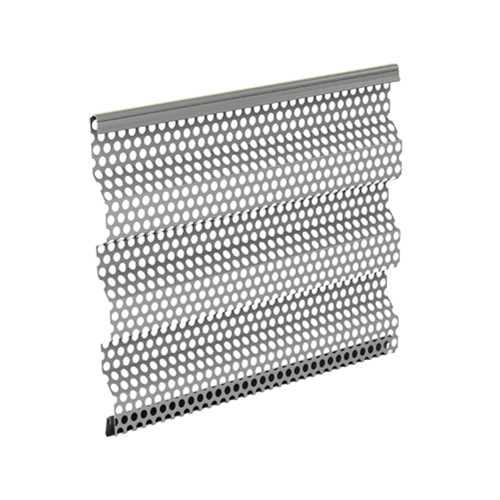

Made of various materials such as aluminum, stainless steel, and plastic. These panels are used for different applications such as wall cladding, ceiling, and flooring.

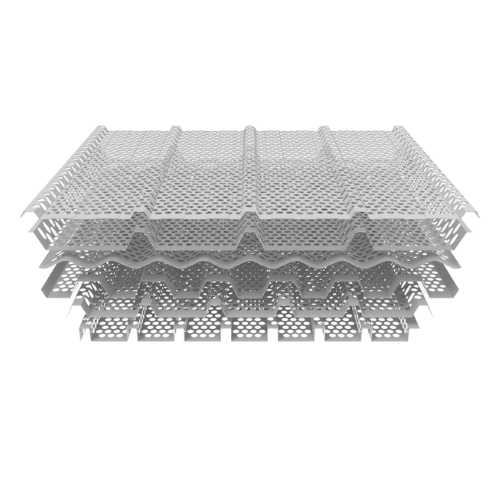

Type of building material made from combining corrugated and perforated metals. They are lightweight, durable, and provide superior insulation.

A strong type of material that is designed to withstand both high and low temperatures. As well as impacts and other wear and tear forms.

Why Choose XIONGQIAN Perforated Composite Panels

The panels are attractive and versatile building materials. They are lightweight, durable, and easy to install. Making them a popular choice for businesses.

Additionally, they are available in a variety of colors and finishes. It means you are allowed to customize your building’s look and feel. Plus! The panels are resistant to weathering. Ensuring a long-lasting, safe, and aesthetically pleasing building.

Related Products

How Perforated Composite Panels are Made

The panels consist of two layers of material that are bonded together. The layers can be made from a variety of materials such as metal, plastic, or composite materials.

The outer layer of the panel is usually made from metal. Usually from steel, aluminum, or stainless steel. This layer provides the strength and durability needed for the application. However, its inner layer is usually made from composite materials such as fiberglass, carbon fiber, or Kevlar. This layer provides the flexibility and light weight of the panel.

Resistance Properties of Perforated Composite Panels

The perforated composite panels can be very resistant to various elements. It depends on their composition and the materials used.

Generally speaking, they are highly resistant to corrosion, heat, fire, and water. They are also resistant to impacts, abrasion, and UV light. Additionally, they can be designed to be sound-dampening and flame-retardant.

Wide Application Areas for Perforated Composite Panels

You can use perforated panels on specific application areas such as:

- Ceilings

- Facades

- Roofs

- Walls

- Indoors/outdoors

- Theater spaces

- Recording studios

- Sound-sensitive areas

- Warehouses

- Factories

- Retail spaces

- airports

- Other public areas

The Coating Options of Perforated Composite Panels

To maximize the life of these panels and protect them from the elements, it is important using a quality coating.

The most common coating option is a high-performance fluoropolymer coating. Fluoropolymer coatings are designed to resist corrosion and abrasion. They also provide excellent color retention and a long-lasting finish. Since fluoropolymer coatings are highly resistant to chemical and environmental factors, they are perfect for outdoor applications.

Another popular coating option is powder coating. Powder coating provides a tough finish resistant to chipping, fading, and cracking. It is also more economical than other coating types. Also available in a wide variety of colors and finishes. Powder coating also offers a quick turnaround time, and is easy to apply.

Finally, a clear coating can be used to protect perforated composite panels from UV rays and other environmental elements. Clear coatings are designed to provide a glossy finish.

List of Machines Used in the Production of Perforated Composite Panels :

- CNC Router: A computer-controlled cutting machine used to cut out a specific shape. It is commonly used to cut out designs for perforated panels.

- Laser Cutter: A precise cutting machine commonly used to cut intricate designs out of perforated panels.

- Punch Press: A machine used to create precise patterns in perforated panels.

- Waterjet Cutter: A machine used to cut materials using a high-pressure stream of water. It is commonly used to cut intricate designs into perforated panels.

Tests Performed to Ensure Quality

There’s a variety of tests performed to assess the performance of the perforated composite panels. This typically includes:

- Testing for compression

- Tensile strength testing

- Flexural strength testing

- Fire resistance tests

- Permeability tests

- Acoustic absorption tests

- Thermal insulation tests

- Corrosion tests

- Impact tests

FAQ

Q: What are the available sizes for perforated composite panels?

A: The panels come in a variety of sizes to suit different applications. Standard sheet sizes are 4’x8′, 4’x10′, and 5’x10′. Custom sizes are also available depending on the manufacturer and the application. The size of the panel will depend on the type of pattern, material, and opening size desired.

Q: Are these panels strong?

A: Yes. Perforated panels are strong and durable. They are composed of a strong polymer material that is reinforced with fiberglass or other materials. This creates a sturdy, lightweight material.

Q: How do you customize the panels?

- Selecting the material: Depending on your needs, we will choose the material that best meets your requirements.

- Selecting the design: The pattern of the perforations can vary significantly. You can select a pattern that is more open or one that is more closed.

- Choosing the size: The panels come in a variety of sizes and thicknesses to accommodate the desired application. You can select the size depending on the space you need.

- Select the coating: You can choose from a variety of coatings, including PVC, polyester, or epoxy.

- Choosing the color: Options include black, white, gray, and more