XIONGQIAN Perforated Copper Sheet

Copper is an ideal material for perforated sheet applications due to its unique combination of strength, corrosion resistance, and aesthetic qualities. It is one of the few metals that can be used in both interior and exterior applications. The sheet can able to withstand harsh temperatures and environments. Copper can also be formed into a wide variety of shapes and sizes. Moreover, this material is naturally resistant to bacteria and other pathogens, making it the perfect choice for food processing and medical applications. Finally, copper is a renewable resource, making it an environmentally friendly choice.

XIONGQIAN is a trusted perforated copper sheet manufacturer in China. We supply a wide range of sheets with a variety of hole sizes, shapes, thicknesses, and patterns. If you require a standard or custom perforated copper sheet for specific purposes, talk to us now!

Wholesale Copper Perforated Sheet By Shape

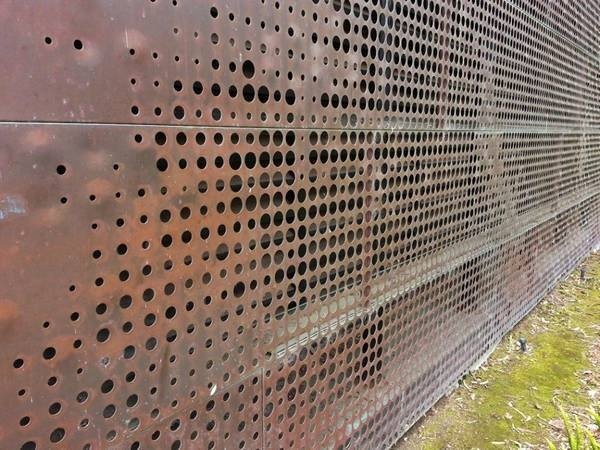

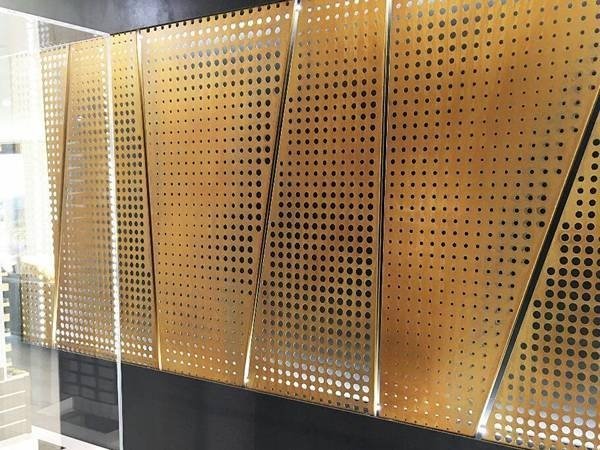

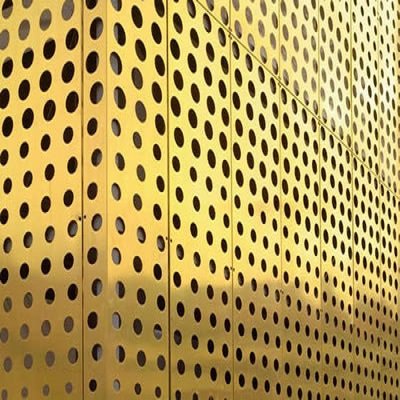

The perforated sheet comes with a round hole shape. It has evenly spaced holes throughout, allowing for easy installation and a secure fit.

Features a unique square-hole design that provides an elegant look to any space. The sheet is made from durable copper that is resistant to rust and corrosion.

Slotted hole shape creates a strong and stable support structure while also allowing air and water to easily pass through. The holes are evenly spaced and the edges are smooth.

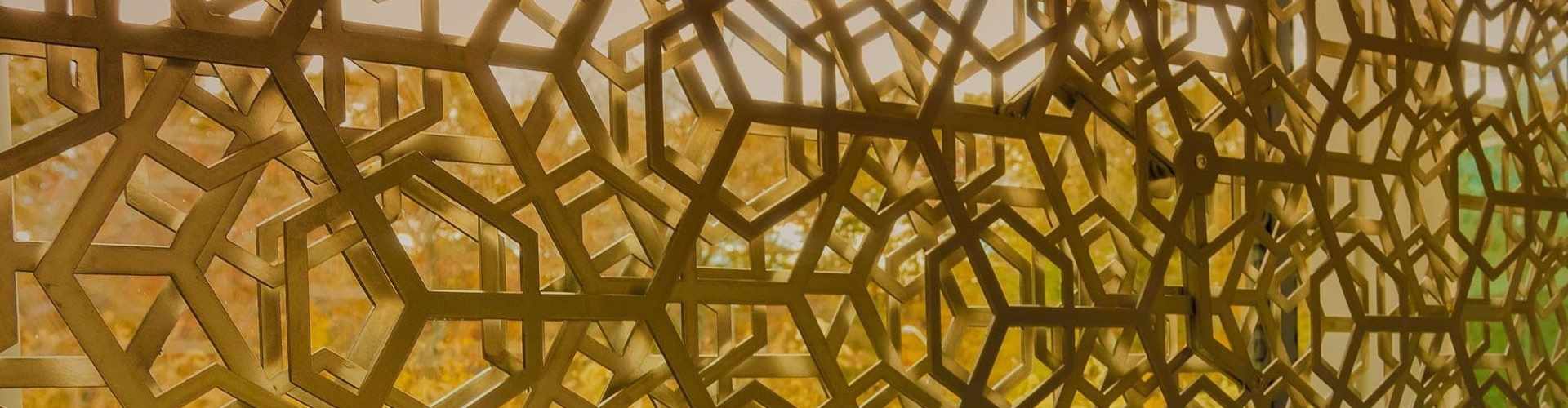

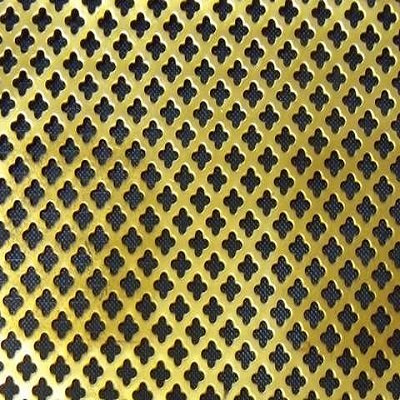

Features a unique hexagonal hole pattern that is perfect for allowing air to pass through while also providing a decorative touch.

Designed with a series of small, evenly spaced oblong holes, allowing for easy and efficient airflow, drainage, and other functions.

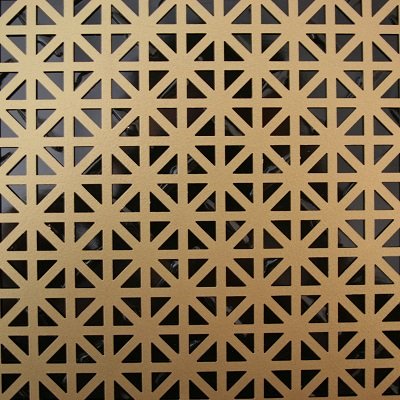

The holes are designed to provide maximum efficiency and strength, while maintaining a sleek and attractive look. This sheet is perfect for a variety of projects and can easily be customized to fit any size or shape.

Ideal choice for a range of decorative and functional applications. It is made from high-quality copper and features a punched pattern of triangle-shaped holes that are evenly spread throughout the sheet

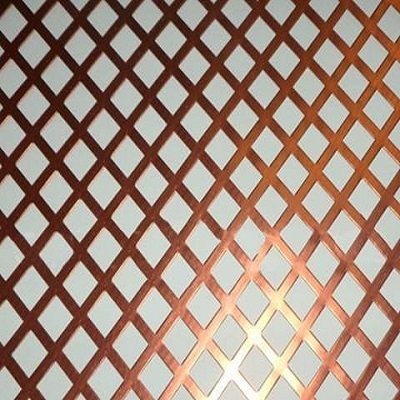

Designed with a unique diamond hole pattern that allows air, water and other liquids to flow through while still providing a strong barrier. Diamond-shaped holes provide a subtle and elegant touch to any project.

Cross-shaped holes allow for superior drainage and airflow, making this sheet ideal for applications that require high levels of air and liquid flow.

Applications of Perforated Copper Sheet

Why Choose XIONGQIAN as Perforated Copper Sheet Supplier?

- We can provide both standard and custom perforated copper sheets, with the ability to create intricate designs and patterns.

- A range of surface finishes, including smooth, dull, and textured.

- Our perforated copper sheet can be cut into specific sizes and shapes for any application.

- We have the capability to anneal, temper, and harden copper sheets for long-term durability.

- Our team can provide professional installation services to ensure a precise fit and finish.

Your industrial project will be more durable and safe with our Perforated Copper Sheet and other Perforated Sheet for sale. We have our own factory and processing line to make qualified perforated copper plate at cheap price.

Related Products

Perforated Sheet Copper Material Grades

- C11000 (electrolytic tough pitch)

- C12200 (oxygen-free high conductivity)

- C14500 (tellurium copper)

- C17200 (beryllium copper)

- C22000 (commercial bronze)

- C26000 (cartridge brass)

- C36000 (free-cutting brass)

- C44300 (low-leaded brass)

Perforated Copper Sheet Hole Arrangement Modes

Staggered: This is the most common hole arrangement mode for perforated copper sheets. The holes are arranged in a staggered pattern, with each row of holes offset from the one above and below it.

Straight: In this arrangement mode, the holes are arranged in a straight line, with no offset between rows.

Diagonal: The holes are arranged in a diagonal pattern, with the bottom row of holes shifted to the left or right relative to the top row.

Alternating: The holes are arranged in an alternating pattern, with the top row of holes shifted to the left or right relative to the second row.

Circular: The holes are arranged in a circular pattern, with all the holes in the same row lined up in a circle.

Extensive Types of Surface Finishes

- Mill Finish: A raw, unrefined surface finish with no additional treatment or coating.

- Polished Finish: A smooth, shiny surface finish achieved by applying a mechanical or chemical polishing process.

- Anodized Finish: An electrochemical process that increases the thickness of the natural oxide layer on aluminum and other metals, providing corrosion protection and increased wear resistance.

- Painted Finish: A painted finish is applied to the surface of the copper perforated sheet to improve its appearance and/or provide additional protection.

- Plated Finish: A thin coating of metal, such as nickel or gold, is applied to the surface of the copper perforated sheet for decoration and corrosion protection.

- Textured Finish: A textured finish is created by applying a texturing process to the surface of the copper perforated sheet, creating a unique appearance and increased slip resistance.

Why Choose Perforated Copper Sheet?

Durability: Copper-perforated sheets are highly resistant to corrosion and rust, making them ideal for outdoor applications.

Versatility: this sheet can be used for a variety of applications, including interior and exterior design, soundproofing, and filtration.

Aesthetics: Feature a distinctive, modern look that adds elegance to any space.

Cost-effectiveness: perforated copper sheets are more affordable than other metal sheets and are easy to install.

Lightweight: our range of perforated copper sheets are lightweight and easy to transport and install, making them ideal for commercial and residential applications.

Manufacturing Processes Used

XIONGQIAN mastered several advanced perforated copper sheet manufacturing methods to deliver the finest products.

- Melting – Copper ingots are melted in a furnace to form a liquid metal.

- Forging – The molten copper is then forged into slabs using a hydraulic press.

- Rolling – The slabs are then fed into a rolling mill and rolled into sheets of desired thickness.

- Annealing – The sheets are then cooled and annealed in an oven to give them flexibility.

- Perforating – The sheets are then perforated with a die or laser to create holes of desired size and shape.

- Finishing – The perforated sheets are then finished through processes such as brushing, polishing, or galvanizing.

- Inspection – The quality of the sheets is then inspected to ensure that they meet the desired specifications.

- Packing – The sheets are then packed and shipped to the customers.

Standard & Certification Compliance of Perforated Copper Sheet

ASTM B370

ASTM B152

ASTM F1667

ASTM B36

ASTM B42

NSF, etc.

Perforated Copper Sheet Function

Perforated copper sheets are created by punching a pattern of small holes into the copper sheet. The holes can vary in size and shape, depending on the desired application. The primary function of these perforated copper sheets is to allow air and other liquids to pass through, while still providing a barrier against other materials. Perforated copper sheets can also be used to reduce noise and vibration levels, as well as to provide a decorative finish to a surface.

Wide Uses of Perforated Copper Sheet Metal

The perforated copper sheet is broadly utilized in various applications.

- Architectural facades, sunshades, and wall cladding

- Filter screens

- Abrasive blasting

- Acoustic panels

- Fire protection

- Security applications

- Vibration dampening

- Heat and light diffusion

- Cable trays

- HVAC ducts

FAQ on Perforated Copper Panels

How long a quality perforated copper sheet will last?

The life expectancy of perforated copper sheets depends on the application and environment. In general, a quality perforated copper sheet can last up to 10-20 years.

Do quality perforated copper sheets never rust?

No, perforated copper sheets can rust over time just like any other type of metal. To prevent rust, regular cleaning and maintenance are required.

How do you ensure quality standard perforated copper sheets?

XIONGQIAN will ensure quality standards of perforated copper sheets by following a few key steps.

- First, we use high-grade copper that is free of any impurities to ensure that the sheet is of the best quality.

- Then, we will also use advanced manufacturing processes and machinery to ensure that the sheet is properly perforated and cut to the desired shape and size.

- Finally, our team uses strict quality control procedures to inspect the sheet for any flaws or imperfections before it is sold to the customer.

How much is the perforated copper sheet price range?

The price of perforated copper sheets ranges from $2.50 to $6.50 per square foot depending on the size, thickness, and pattern of the sheets.