XIONGQIAN Wire Mesh

Wire mesh is a durable material made of interconnected metal wires. It is used in a variety of applications, including fencing, security barriers, sieves, and filters. Metal wire mesh is available in a variety of metals, including aluminum, brass, stainless steel, and galvanized steel. It can also be coated with a protective material, such as PVC, to extend its life and improve its resistance to corrosion. Metal wire mesh is a strong and cost-effective solution for many applications.

XIONGQIAN is a professional wire mesh supplier and manufacturer in China. We have the right equipment and manufacturing technology to fabricate wire mesh patterns and sizes. Whether you need a wire mesh for construction, as reinforcement in concrete, or in architecture, we have the perfect solutions. Message us today!

Wire Mesh By Material

Welded wire mesh is a type of flexible, strong and versatile metal material used in many construction and manufacturing applications. Made by welding two or more wires together to form a grid-like pattern.

Stainless steel wire mesh is a woven metal wire mesh with a stainless steel alloy. It is a corrosion-resistant material that is ideal for use in a variety of industries, including chemical and pharmaceutical, food, automotive, etc.

Carbon steel wire mesh is corrosion-resistant and heat-resistant, making it well-suited for outdoor use. Carbon steel wire mesh is available in a wide range of sizes and styles, making it a great option for many industrial and commercial needs.

Storage unit with a metal frame and a wire mesh body. It is used to store and transport items securely while providing visibility and breathability to the items stored within. This type of container is often stackable and can be used in a variety of applications.

Architectural wire mesh is a versatile material that can be used to provide a unique aesthetic to any building. It adds a modern twist to any interior or exterior design, while providing a durable, secure, and visually appealing solution.

Why Choose XIONGQIAN

XIONGQIAN offers a variety of metal wire mesh options in a wide selection of metal wire mesh products in various sizes, colors, and materials. These are meticulously designed to meet a wide range of applications. We also offer custom-made wire mesh products to meet individual requirements. Our company provides quality assurance, cost-effectiveness, technical support, and on-time delivery.

From qualified raw materials to qualified wire mesh, we go through three rounds of control and testing. During the wire mesh production, XIONGQIAN will make quality inspection of hole diameter, hole spacing and thickness is critical to ensure xact specifications.

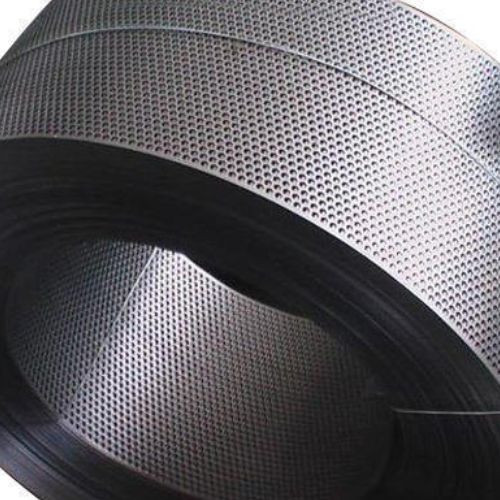

XIONGQIAN also fabricate custom Perforated Steel Sheet for more application, you can inquiry us if there’s sourcing need.

Related Products

Wire Mesh Fabrication

Wire mesh is typically manufactured by first weaving together strands of wire to form a sheet. This sheet is then cut and bent into a variety of shapes and sizes. The process of creating wire mesh involves several steps, including:

Weaving

The first step is to weave wires together to form a sheet. This is done on a loom, which is a machine that is used to weave fabrics together. The loom holds the wires in place and moves them as necessary to form the desired pattern.

Cutting

Once the sheet is woven, it is then cut into the desired shapes and sizes. This is usually done with a cutting machine, which is designed to accurately cut the wire mesh into specific shapes.

Bending

After the wire mesh is cut, it is then bent into its desired shape. This is usually done by hand or with a machine that is designed to bend the wire into the desired shape.

Finishing

The final step is to finish the wire mesh to make sure that it is smooth and free of any sharp edges. This can be done with a grinding or polishing machine, which is designed to smooth out any imperfections in the wire mesh.

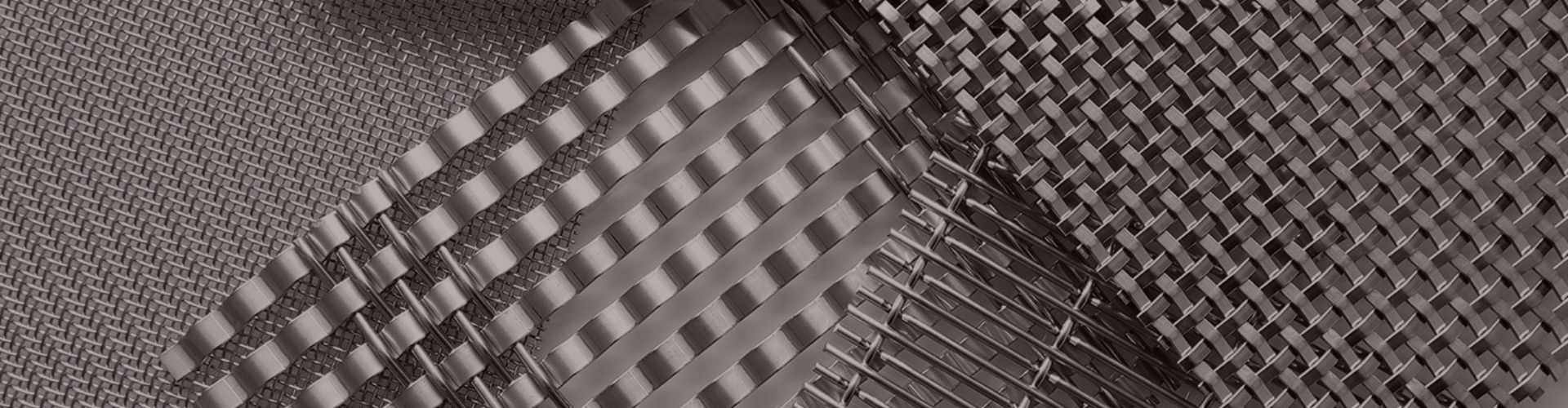

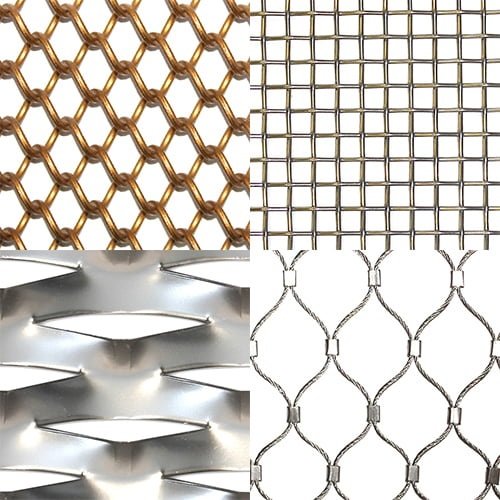

Various Patterns and Designs Available

Parallel Wire Weave – This pattern features parallel wires that are woven together to form a uniform pattern.

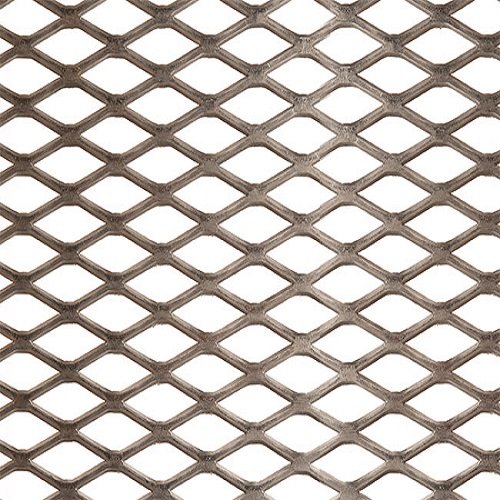

Diamond Weave – Features a diamond shape formed by multiple interwoven wires.

Chain Link – This pattern features wires that are twisted together to form a chain link pattern.

Crimped Wire – Features wires that are crimped together in a uniform pattern.

Hexagonal Weave – It has a multiple interwoven wires that form a hexagonal pattern.

Square Mesh – Design features multiple interwoven wires that form a square mesh pattern.

Extensive Range of Wire Mesh Surface Treatments

- Galvanizing: Galvanizing is a process in which a layer of zinc is applied to the surface of the wire mesh to protect it from corrosion and rust.

- Powder Coating: Powder coating is a process in which a layer of colored powder is applied to the wire mesh to provide a decorative finish and additional protection from corrosion.

- Anodizing: Anodizing is a process in which an oxide layer is formed on the surface of the wire mesh to provide additional protection from corrosion and increase the durability of the material.

- Painting: Painting is a process in which a layer of paint is applied to the wire mesh to provide a decorative finish and additional protection from corrosion.

- Waxing: Waxing is a process in which a layer of wax is applied to the wire mesh to provide a protective barrier against corrosion and rust.

Wire Mesh Advantages

- Wire mesh is a cost-effective material for a variety of applications, offering a high strength-to-weight ratio, corrosion resistance and airflow.

- It is easily cut, shaped and formed, allowing for quick and easy installation.

- Available in a wide range of sizes, gauges and materials, making it suitable for a wide range of applications.

- Wire mesh offers a high degree of security, making it ideal for use in security or safety-related applications.

- A great option for use in filtration, as it can easily filter out particles of different sizes.

- Wire mesh is lightweight and easy to transport, making it a great option for both indoor and outdoor applications.

- It is also a great option for animal enclosures, as it is durable and can handle the elements.

Quality And Standard Certifications

Wire mesh quality is determined by a variety of factors, including the type of metal used, the mesh size and shape, and the way it is woven. To ensure that a wire mesh meets industry standards, they are certified by a reputable testing laboratory. Common certifications include ISO 9001, ASTM International, and the American Society for Testing and Materials (ASTM).

FAQ

What are wire mesh standard diameters?

Wire mesh standard diameters typically range from 0.009 inches to 3 inches. However, the exact size of the wire mesh standard diameter will depend on the intended application. For example, some wire mesh used in sieving applications may have diameters as small as 0.004 inches, while heavier-duty applications such as animal fencing may require larger diameters of up to 6 inches.

Which is better: wire mesh or fiber?

It depends on the application. Fiber is generally used for high-speed data transmission, while wire mesh is better for more secure connections with less interference. Each has its own advantages and disadvantages, so it is important to consider the specific needs of the application before deciding which is best.

What metal material is best for wire mesh?

The best metal material for wire mesh depends on the application. For projects requiring corrosion resistance and strength, stainless steel is a good choice. For projects that require flexibility and ductility, aluminum and galvanized steel are good options.

How do you ensure wire mesh quality?

XIONGQIAN ensures wire mesh quality by using high-quality raw materials, following a strict production process, and testing the finished product for conformance with industry standards. During the production process, we inspect each step to ensure the wire mesh has been correctly woven and crimped, and that the mesh is of the correct size, shape, and thickness. After production, our testing team tests the wire mesh for strength, elongation, and corrosion resistance to ensure it meets the required specifications.